Orca Slicer Configuration

Orca Slicer is one of the best free and open-source 3D printing slicers available today. It combines powerful features with an easy-to-use interface, making it perfect for both new users and experienced 3D printing enthusiasts.

If you’re switching from another slicer or using Orca Slicer for the first time, setting it up for your specific printer might seem confusing. But don’t worry, this complete Orca Slicer setup guide will help you understand every setting step by step. You’ll learn how to configure your printer quickly and get the best print quality with ease.

Navigation

Printer Settings

Setting up your printer correctly in Orca Slicer is the key to fast, accurate, and damage-free 3D printing. With the right configuration, you can achieve better print quality, reduce waste, and save time.

In this guide, you’ll learn how to adjust Orca Slicer printer settings for the best results. Whether you’re printing small models or large prototypes, Orca Slicer’s built-in tools and profiles make it simple to customize your printer according to your specific project.

Air Filtration and Exhaust Fan Settings

If your 3D printer uses a separate air filtration system or exhaust fan to remove VOCs (Volatile Organic Compounds) and UFPs (Ultra-Fine Particles) from the printing chamber, Orca Slicer makes it easy to manage them.

You don’t need any extra plugins or external software because Orca Slicer includes built-in options that allow you to control and configure these fans directly through its command settings. By adjusting these air filtration and exhaust fan settings, you can improve the safety and cleanliness of your printing environment while ensuring consistent print quality.

Auxiliary Fan Settings

Auxiliary fans play an important role in maintaining high print quality by cooling the extruded filament immediately after the first layer is printed. This quick cooling helps prevent warping, sagging, and layer shifting, especially when working with temperature-sensitive materials.

Properly setting up your auxiliary fan settings in Orca Slicer ensures that cooling happens at the right time and intensity for each print. These settings not only improve the overall finish of your 3D model but also allow for faster printing speeds without affecting accuracy.

By learning how to control and adjust your auxiliary fan directly from Orca Slicer, you can manage your printer’s cooling process within the same software, making the workflow easier and more efficient.

Chamber Temperature Control

The chamber temperature plays a crucial role in determining the quality and strength of your 3D prints. Controlling it correctly helps prevent common printing issues such as warping, cracking, and uneven layer bonding.

Before printing your first model, it’s important to understand the ideal temperature range for your material and how to maintain it throughout the process. Different materials require different chamber conditions to perform at their best.

In Orca Slicer, you can easily manage chamber temperature by selecting built-in presets or creating custom temperature controls using simple configuration commands. These settings allow Orca Slicer to automatically regulate your printer’s environment, so you don’t need additional hardware or monitoring tools.

Adaptive Bed Mesh

The adaptive bed mesh is the foundation of your 3D print, forming the first and most critical layer of your model. It determines how well your filament adheres to the print bed and sets the base for the entire structure.

A properly configured adaptive mesh ensures that the bed surface is level, allowing the filament to be deposited evenly across all points. This prevents common first-layer issues such as warping, uneven adhesion, or dimensional inaccuracy.

By fine-tuning the adaptive bed mesh settings in Orca Slicer, you can achieve a perfectly balanced first layer, ensuring that every print maintains its precision, stability, and flawless dimensional accuracy from start to finish.

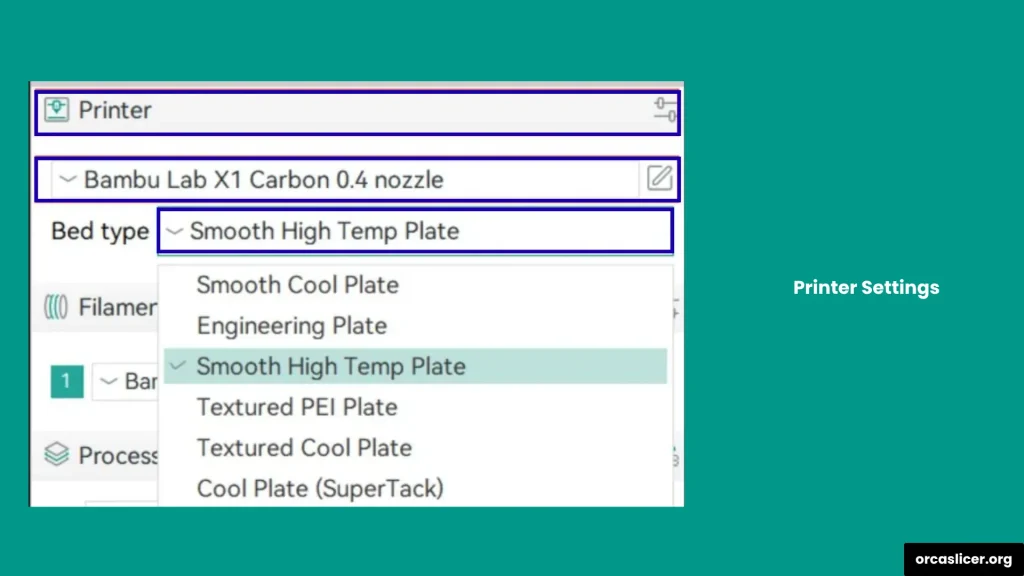

Multiple Bed Types Settings

If you’re new to 3D printing or love experimenting with DIY projects, understanding the different bed types and their settings is essential for achieving perfect print results. Each bed type reacts differently to temperature, adhesion methods, and materials, so proper configuration is key.

In Orca Slicer, you can easily customize your printer bed settings to match your printing needs. The slicer allows you to choose from multiple bed types and define the ideal temperature range for each one based on the filament material and print size.

Whether you’re using glass, magnetic PEI, textured steel, or flexible beds, Orca Slicer helps you set the correct bed temperature and surface parameters to ensure optimal adhesion, easy removal, and flawless first layers.

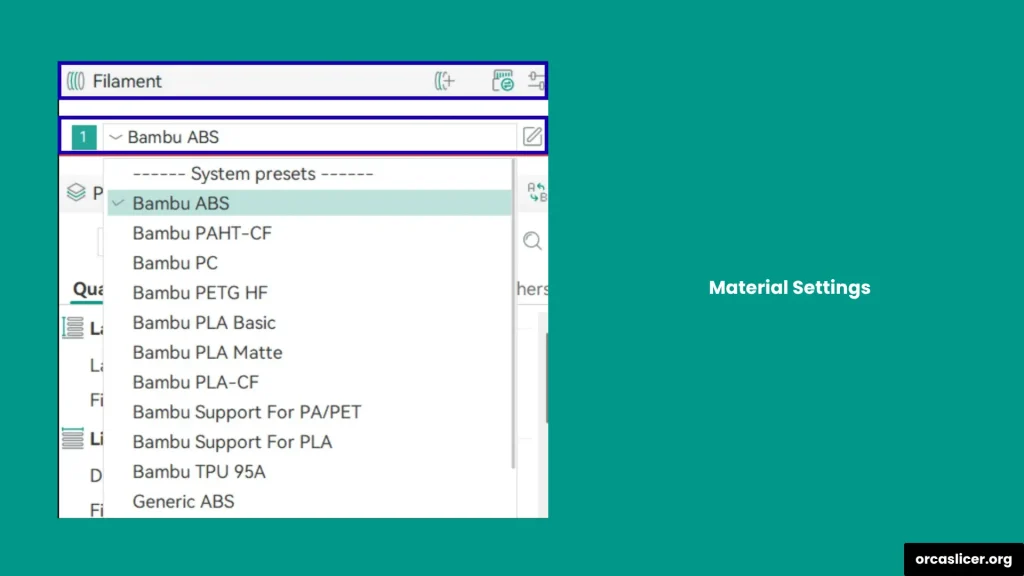

Material Settings

In 3D printing, every material has its own set of requirements for print speed, temperature, fan control, adaptive bed mesh, and bed type. Ignoring or misconfiguring these settings can lead to poor print quality, wasted filament, or even damage to the printer.

By setting the right material configuration, you can achieve strong adhesion, precise layer bonding, and a flawless surface finish every time you print.

This section will guide you on how to tune your printer settings for each filament type so your prints are optimized for speed, temperature stability, and quality without risking print failure.

Single Extruder Multimaterial

When using a single extruder for multimaterial printing, you need to configure a few additional settings to ensure smooth material transitions and consistent print quality. This setup allows your printer to handle different filaments or colors in a single print job while maintaining precision.

In Orca Slicer, you can define settings for the prime tower, ramming, and filament change options directly within the slicer. The prime tower acts as the base area where excess filament is purged and prepared before switching to a new material, ensuring clean color changes and proper extrusion flow.

You can also specify parameters like the prime tower position, temperature for ramming, and filament change speed to optimize the transition process. These options are especially useful for multi-color or multi-material prints, where each filament requires unique temperature and flow settings.

Pellet Printers and Pellet Flow Coefficient

In large-scale 3D printing, traditional filaments are often replaced by pellets, which are small granules of raw material used to print larger objects. The process is similar to Fused Deposition Modeling (FDM) but differs in how the material flow is managed and measured.

In pellet-based printers, the material calculation is not based on filament volume but rather on the pellet flow coefficient. This coefficient determines how much material flows through the extruder per second and helps the printer maintain consistent extrusion rates.

Understanding the difference between pellet printing and filament printing is important for achieving accurate results. While filament printers rely on length and volume for material measurement, pellet printers focus on flow rate and feed consistency. Setting the correct pellet flow coefficient in Orca Slicer ensures that the printer delivers the right amount of material for every layer, resulting in smooth surfaces, strong layer adhesion, and high-quality large-format prints.

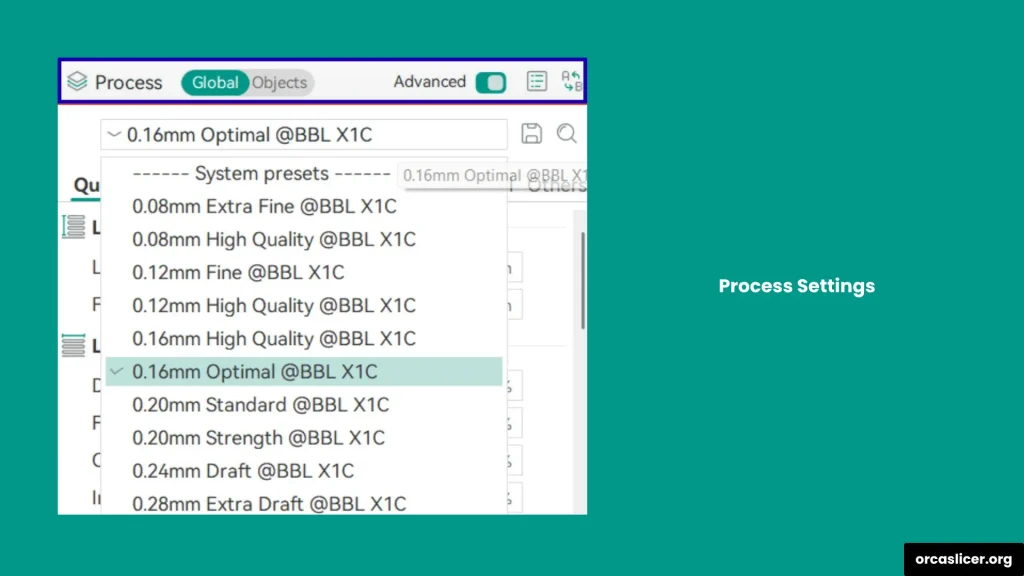

Process Settings

After setting up your printer configuration, fan control, auxiliary fans, print speed, and material parameters, the next important step is to define and monitor your process settings. These settings act as the key performance indicators (KPIs) for your print, helping you maintain consistent quality from start to finish.

Before starting your first print, it’s essential to understand and calibrate each process setting carefully. This ensures that every component, from extrusion flow to temperature control, works together perfectly for smooth, high-quality 3D printing results.

Quality Settings

Quality settings determine the visual appearance, surface finish, and overall precision of your 3D print. Every small adjustment in these settings directly affects how smooth, detailed, and accurate your final model will be.

These parameters allow you to control aspects such as layer height, extrusion width, perimeter count, and infill density, all of which contribute to the print’s aesthetic and structural quality. Taking time to fine-tune these settings ensures that every print not only performs well but also looks professional and refined.

Each step in the quality configuration process matters, as it defines the balance between speed, detail, and strength, which are the key factors behind every successful 3D print.

Layer Height

Layer height is one of the most important factors that define the surface finish and detail level of your 3D print. It represents the thickness of each printed layer and directly affects both the print quality and printing time.

In simple terms, layer height is inversely proportional to print quality. The smaller the layer height, the smoother and more detailed your print will look. However, smaller layers also increase printing time. On the other hand, a larger layer height speeds up printing but reduces the surface smoothness and fine detail.

Line Width

Line width refers to the thickness of the extruded filament that forms each printed line during 3D printing. It determines how much material is laid down for every path the nozzle makes.

By adjusting this setting, you can control how thick or thin each printed line will be, which directly impacts surface quality, print strength, and detail resolution. You can configure the line width in two ways:

- By setting a fixed value in millimeters (mm).

- By defining it as a percentage of the nozzle diameter.

Seam Settings

In 3D printing, every model has a starting and ending point for each layer, which together form a seam on the surface of the print. This seam is where the nozzle begins and finishes extruding material, and its placement can significantly affect the final appearance of your model.

Seam settings allow you to control where and how the seam appears, helping you minimize its visibility and improve the print’s overall quality. By adjusting these parameters, you can hide or align the seam in less noticeable areas, reducing the need for post-processing or sanding.

Precision

Under the Quality Settings tab in Orca Slicer, you’ll find the Precision section which is a powerful set of tools that let you fine-tune your print’s accuracy, dimensional stability, and surface detail.

These settings control how closely your 3D print matches the digital model, ensuring cleaner edges, tighter fits, and a more professional look. The key parameters include Gap Closing, Resolution, Arc Fitting, XY Size Compensation, Elephant Foot Correction, Precise Z Height.

Ironing Settings

The Ironing feature in Orca Slicer is designed to give your 3D prints a smooth, polished top surface. As the name suggests, ironing works like running an iron over your print. It reprints the topmost layer using a slower movement and lower extrusion flow to flatten surface lines and fill minor gaps.

This process doesn’t add new layers; instead, it moves the nozzle over the existing top layer at the same height, depositing a thin amount of molten filament to even out imperfections. The result is a glossier, uniform finish that enhances both the appearance and texture of the print.

Wall Generator

The Wall Generator settings in Orca Slicer control how the inner and outer walls of a 3D print are formed, ensuring that every layer is extruded with consistent thickness, precision, and strength. These settings play a major role in maintaining dimensional accuracy, surface quality, and overall print stability.

When printing, walls define the boundary between the inner infill and the outer visible surface. Therefore, how these walls are generated directly affects the print’s visual finish, mechanical strength, and printing efficiency. Orca Slicer’s Wall Generator allows you to fine-tune parameters like transition angles, wall filtering, distribution, and speed, helping your print achieve the perfect balance between detail and durability.

Walls and Surfaces

If you want better precision and surface quality in your 3D prints, the Walls and Surfaces settings in Orca Slicer let you manage them effortlessly.

This module helps you control the inner and outer wall parameters, printing order, and infill behavior while also optimizing wall loop direction for smoother results. By adjusting these options, you can enhance the overall strength, accuracy, and finish of your models thus achieving clean, detailed, and professional-quality prints directly from Orca Slicer.

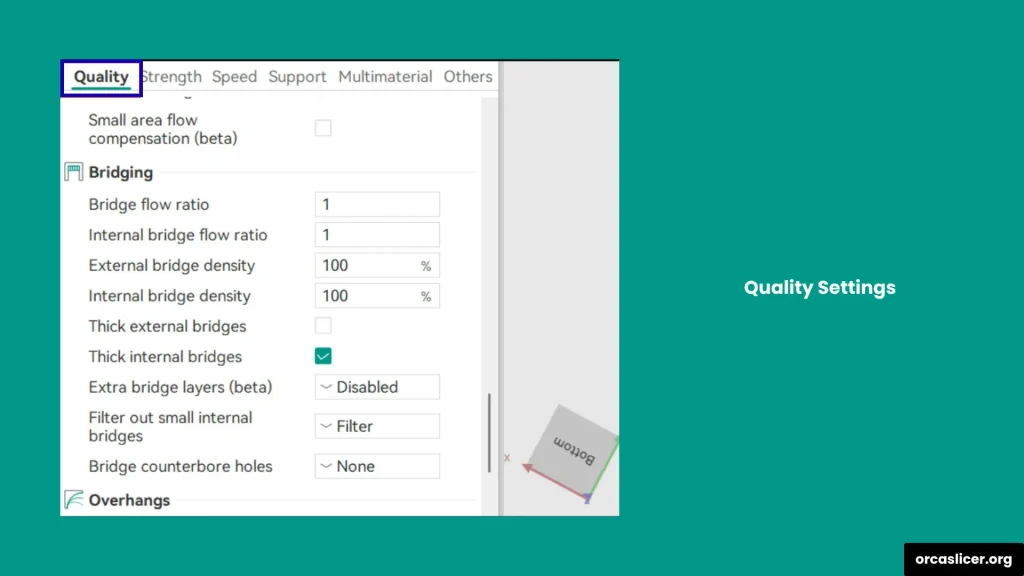

Bridging

The Bridging settings help you print parts that have gaps, holes, or open spaces without losing quality. Bridging happens when the printer creates a filament line across a gap just like building a tiny bridge between two points.

Without the right bridging setup, your 3D prints can suffer from filament sagging, uneven top layers, or poor strength in open areas. But with Orca Slicer’s bridging options, you can easily fine-tune the flow rate, bridge speed, thickness, and density to get strong, clean bridges with smooth surfaces.

By adjusting these settings, you can eliminate drooping lines and improve how your printer handles overhanging gaps or suspended layers, ensuring a solid, high-quality top layer every time.

Overhangs

Printing overhangs is one of the most challenging parts of 3D printing because it requires careful balance between speed, cooling, and wall settings. If not managed properly, overhangs can lead to drooping edges, rough surfaces, or weak layers.

In Orca Slicer, you can easily fine-tune overhang performance using a variety of tools. These include options to control the overhang wall behavior, maximum angle, hole area, reverse threshold, and several other important parameters.

With the right overhang settings, your printer can handle steep angles smoothly and produce clean, detailed surfaces without the need for excessive supports.

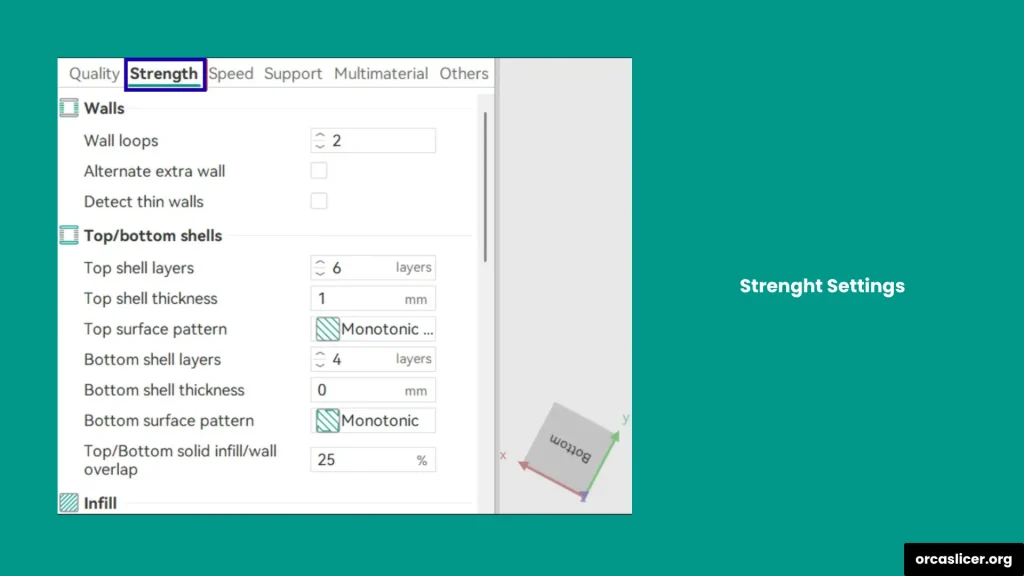

Strength Settings

The Strength Settings help you make your 3D prints stronger and more durable without compromising on surface quality or dimensional accuracy. While a smooth finish looks great, the real test of a good print is how well it holds up under stress.

By understanding and adjusting the right parameters, you can increase the structural strength of your models, improve their layer bonding, and ensure your final product lasts longer. Optimizing these settings is essential for prints that need both precision and long-term durability.

Walls

The walls form the outer lining of your 3D print, giving the model its visible surface, shape, and overall strength. Walls play a key role in determining the surface finish, layer adhesion, and durability of your print.

The wall settings in the Strength Tab of Orca Slicer allows you to fine-tune several parameters to get the perfect balance between speed, quality, and structural integrity. You can detect wall loops, repair thin walls, add extra perimeters, and test how wall thickness affects your model’s overall strength.

By adjusting these wall settings, you can make your print stronger without wasting material. Proper wall configuration ensures that your outer layers bond tightly, resist cracking, and maintain a professional, smooth finish even at high speeds.

Top and Bottom Shells

The Top and Bottom Shells settings in Orca Slicer allow you to control how the upper and lower surfaces of your model are printed. These shells are responsible for sealing the internal infill and giving your print a neat, solid appearance.

Here, you can customize multiple options such as:

- Shell Layer Count to determine how many solid layers appear on the top and bottom.

- Shell Thickness for added strength and stiffness.

- Surface Density to control how solid or light your surface feels.

- Infill and Wall Overlap to improve bonding between layers.

- Surface Pattern to define how the top and bottom textures look.

All these options are part of Orca Slicer’s Strength Settings, giving you full control over both the mechanical strength and visual quality of your final product. By adjusting them correctly, you can ensure the print remains durable, smooth, and visually appealing.

Infill

The infill is the internal structure that supports the outer walls of your 3D print. It determines how solid or lightweight your print will be. In Orca Slicer, you can precisely control the infill density, overlap, pattern, and material flow to achieve the perfect balance between strength and material efficiency.

A higher infill density increases durability and weight, while a lower density reduces filament usage and print time. You can also adjust settings like gap fill, filtering out tiny gaps, and infill anchors to make sure internal layers align properly and stay stable throughout the print.

Fine-tuning these infill settings allows you to build prints that are not only strong but also efficient in material use, making them ideal for both functional parts and decorative models.

Fill Patterns

The Fill Patterns setting defines the geometric pattern used to fill the interior of your print. The pattern you choose affects the strength, flexibility, and print time of your model.

Common patterns include grid, gyroid, honeycomb, and cubic. While they may look similar, each has unique advantages. For example, gyroid offers excellent strength in all directions, while grid provides a faster and more efficient print for general use.

Selecting the right pattern based on your model’s design and purpose can improve the mechanical performance of the print and reduce unnecessary material use.

Template Metalanguage for Infill Rotation

The Template Metalanguage for Infill Rotation gives you precise control over how the infill is oriented and rotated within each layer. You can choose simple options like fixed angles or define complex templates that adjust infill direction automatically.

This customization helps align infill lines with the shape of your model, improving structural strength and reducing weak spots. Adjusting infill direction also helps distribute stress more evenly, especially for functional prints that must withstand bending or twisting.

Advanced Strength Settings

The Advanced Strength Settings section offers deeper control over how the internal structures of your print behave. Here, you can:

- Align infill direction with the model’s geometry.

- Adjust the bridge infill direction for better layer support.

- Minimize the sparse infill threshold to reduce weak internal spots.

- Enable detection of narrow internal solid infills for better print accuracy.

These settings allow you to adjust every detail of your print’s internal structure. With proper adjustment, you can ensure your model maintains its strength, precision, and balance from the first layer to the last.

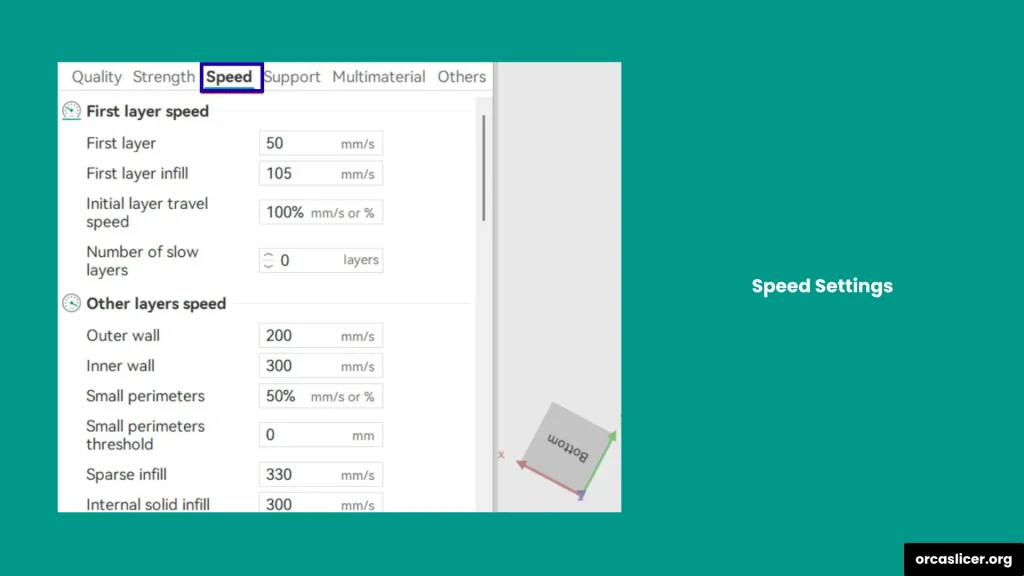

Speed Settings

The Speed Settings let you control how fast your printer moves and extrudes filament during the entire 3D printing process. Finding the right balance between speed and precision is key to achieving both high-quality prints and shorter print times.

Here, you can adjust the speed for different stages of the print, including the first layer, walls, overhangs, travel moves, acceleration, and extrusion rate. Each of these plays an important role in how your print adheres, forms, and finishes.

Let’s look at each setting in detail and see how it affects your 3D printing performance.

Initial Layer Speed

The Initial Layer Speed controls how fast the first layer of your model is printed. It is usually kept slow, which helps the filament stick firmly to the print bed.

A slower first layer improves bed adhesion, reduces warping, and creates a stable foundation for the rest of the print. Most users prefer a speed between 20 to 40 mm/s for the initial layer, depending on the material and printer type.

Other Layer Speeds

Once the first layer is printed successfully, you can increase the speed for the remaining layers. In Orca Slicer, you can set different speeds for:

- Outer walls for clean surface finishes.

- Inner walls for faster structural filling.

- Infill regions for balancing strength and print time.

- Top and bottom shells for consistent surface smoothness.

You can also adjust acceleration and jerk settings here to make sure the printer handles corners and direction changes smoothly without losing precision.

Overhang Speed

The Overhang Speed setting helps you control the print speed for angled or unsupported areas of your model. Reducing speed on steep overhangs improves accuracy and prevents the filament from drooping.

You can set different speeds depending on the angle of the overhang. Steeper angles require slower speeds for better quality, while mild overhangs can be printed faster without losing detail.

Travel Speed

Travel Speed defines how fast the printer’s head moves when it is not extruding filament. Setting the right travel speed helps minimize stringing, blobs, and ringing artifacts on the surface.

Too slow travel speeds increase print time, while very high speeds can cause vibrations. A balanced value ensures smooth movements without missing steps or losing print accuracy.

Acceleration

Acceleration controls how quickly the printer reaches its target speed when starting or stopping movement. In most printers, this is defined in the firmware, but Orca Slicer allows you to set a limit if your printer’s acceleration is not configured properly.

Lower acceleration values improve precision, especially for small details and corners, while higher values make printing faster but may reduce accuracy. Adjusting this carefully helps prevent ringing and layer misalignment.

Jerk (XY)

The Jerk setting determines how abruptly the printer changes direction during movement. It affects how quickly the print head can switch between different paths without slowing down completely.

Proper jerk tuning ensures smoother transitions between layers and prevents unwanted vibrations or layer shifting. Keeping this value moderate helps maintain both speed and stability.

Advanced Speed Settings (Extrusion Rate Smoothing)

When printing at high speeds or using large flow rates, you may face issues such as bulging, under-extrusion, or missing sections. The Extrusion Rate Smoothing (ERS) feature in Orca Slicer helps you manage these problems.

ERS works by gradually adjusting the extrusion rate during fast speed changes. This creates consistent material flow and prevents uneven filament buildup. It is especially useful for high-speed or large-volume printing, where precision and smooth transitions are critical.

By fine-tuning these advanced speed controls, you can achieve fast, reliable, and professional-quality prints.

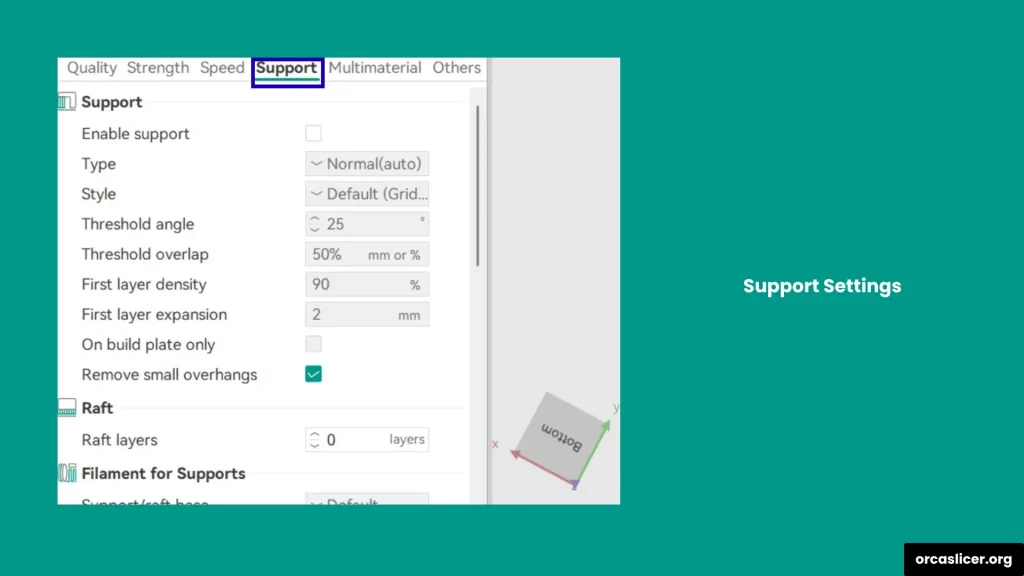

Support Settings

In 3D printing, support structures play a crucial role in maintaining the stability of models that have overhangs, bridges, or complex geometries. Without proper support, prints can collapse or show visible deformities.

In Orca Slicer, you can easily create, optimize, and customize support structures to improve your print quality while reducing material waste. The slicer provides a full range of support options that let you control every aspect of support design, from the base layer to advanced parameters like angles and density.

Let’s look at each support setting in detail.

Support

The Support helps you generate structures that hold up difficult or unsupported areas of your model during printing. These supports prevent sagging, curling, or collapsing in areas such as steep overhangs or bridges.

By adjusting support density, pattern, and placement, you can make sure your model is stable while keeping removal easy after printing. Choosing the right support type improves both accuracy and surface finish on complex parts.

Raft

The Raft is a base layer printed beneath your model to improve bed adhesion. It helps the first layer stick firmly to the print bed, reducing the risk of warping or detachment during printing.

Rafts are especially useful when printing with materials like ABS, which can shrink or lift off the bed. You can adjust raft thickness, air gap, and pattern to ensure your print starts on a stable foundation.

Support Filament

The Support Filament setting allows you to choose a specific filament type for printing support structures. This is useful if you want to use a different material for supports, such as a dissolvable or breakaway filament.

You can customize various support material parameters, including the base layer, interface density, and support type, to minimize filament usage. This helps reduce material waste while keeping your supports strong and easy to remove.

Support Ironing

Support Ironing in Orca Slicer works just like ironing for the main model. It smooths the top surface of support structures by lightly re-melting the filament to remove small bumps or rough textures.

This feature is important for models where the supported areas will be visible or need to have a clean, flat finish. Adjusting ironing speed and flow can improve how well the top layers of your model sit on the supports.

Advanced Support Settings

The Advanced Support Settings give you deeper control over how supports are printed. You can adjust parameters such as:

- Z distance to define the gap between the support and the model.

- Support wall loops for additional reinforcement.

- Base pattern spacing and angle for stronger adhesion.

- Layer expansions to improve stability and coverage.

Tree Supports

The Tree Supports feature in Orca Slicer offers an efficient way to generate supports that look like branching trees. These are perfect for organic or irregular shapes that need lightweight, flexible support structures.

You can customize:

- Tip diameter for precise contact with overhangs.

- Branch distance and diameter for balance and strength.

- Branch density and angle for better distribution and support coverage.

Tree supports are easier to remove, use less material, and reduce marks on the printed surface, making them a favorite choice for complex 3D models.

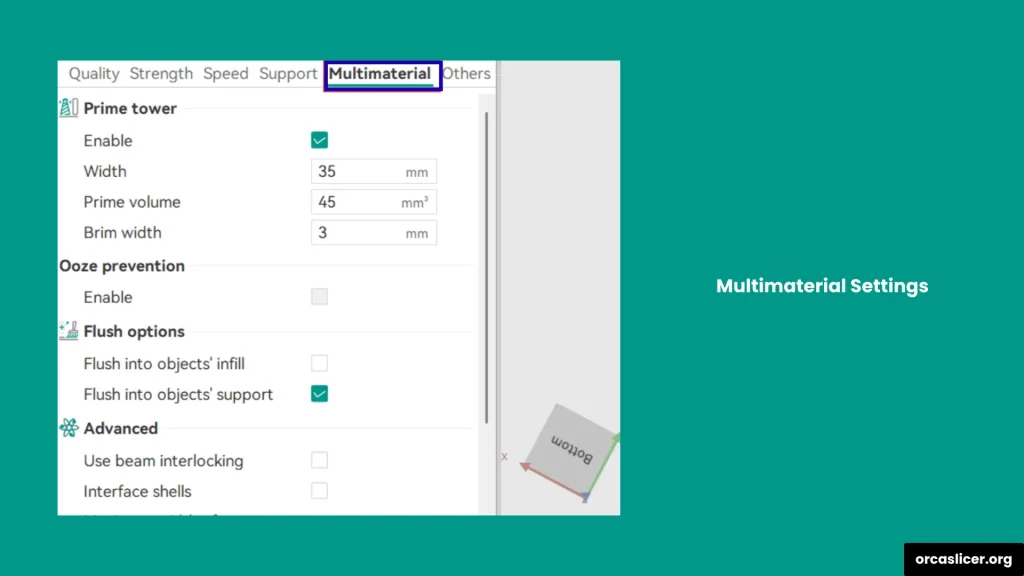

Multimaterial Settings

Many 3D printers today can print with two or more filaments, which means you can mix different colors or materials in the same model. In Orca Slicer, the Multimaterial Settings help you control how these materials are used and switched during printing.

By understanding these settings, you can make your prints cleaner, stronger, and more colorful. You can prevent leaks, reduce waste, and make the transitions between materials smooth and accurate.

Orca Slicer gives you full control over everything, from the way filament changes to how the printer cleans the nozzle between tool swaps. Let’s look at all these options in detail.

Prime Tower

The Prime Tower is a small structure printed beside your main model. Its job is to remove old filament and prepare the nozzle for the new filament before printing continues on your model.

When you change colors or materials, the old filament might still be inside the nozzle. Printing a prime tower helps remove that leftover material so the new filament starts clean.

Why Prime Tower is Important

- It keeps color transitions clean, especially when printing multi-color models.

- It stabilizes pressure inside the nozzle, making extrusion smooth.

- It prevents mixing or smearing between materials.

Tips for Prime Tower Settings

- Keep the tower height close to the height of your model so purging remains consistent.

- Make the base wide enough to stay stable on the bed.

- Use moderate purge amounts to balance quality and filament usage.

- If your tower keeps falling over, add a brim for extra grip.

The prime tower might take extra time and material, but it ensures that your multi-material prints look neat and professional.

Filament for Features

If you are using a multimaterial extruder printer, Orca Slicer allows you to assign a specific filament to each part of the model.

You can choose which filament prints:

- Outer walls (to control surface color and finish).

- Inner walls (for strength and bonding).

- Infill (to save expensive filament by using a cheaper one inside).

- Supports (for easy removal with breakaway or dissolvable filament).

- Prime or wipe tower (for cleaning during tool changes).

Example: If you are printing a character figure, you can assign a colored filament for the outer layer and a cheaper white filament for the infill. This way, the model looks perfect on the outside while saving material inside.

This setting helps you control cost, improve visual quality, and manage material efficiently.

Ooze Prevention

When you print with more than one extruder, the inactive nozzle may still release small drops of filament while it is not in use. This can create unwanted strings or marks on the print.

The Ooze Prevention setting solves this problem by lowering the temperature of the inactive extruder. Once the printer switches back to that filament, the nozzle heats up again.

Tips for Ooze Prevention

- Set a lower standby temperature (around 160°C–180°C for PLA) to stop oozing.

- Use a slight retraction before tool change to pull filament back.

- Combine this setting with wipe movements to clean off any extra material.

This feature is especially helpful when working with materials that ooze easily, like TPU, PETG, or flexible filaments.

Flush Options

The Flush Options control how the printer cleans the nozzle when switching between filaments. During flushing, the old filament is pushed out and replaced with the new one to ensure clean color transitions.

In Orca Slicer, you can choose to flush filament inside the infill of your print. This saves material because the cleaning filament gets used inside your model instead of being wasted on the prime tower.

Why Use Flush Options

- Reduces filament waste.

- Cleans the nozzle automatically.

- Prevents unwanted color mixing.

- Speeds up the material change process.

Advanced Settings

The Advanced Multimaterial Settings in Orca Slicer allow you to fine-tune every small detail for maximum control and print quality.

Here you can manage:

- Interlocking beams (for better part connection).

- Shells and beam depth (to improve bonding and surface strength).

- Layer adjustments (to control how materials are layered for different effects).

- Wipe lengths and direction (to reduce stringing and keep edges smooth).

These settings are useful when printing functional parts or decorative multi-color models where strength and accuracy are both important.

By combining all these options, you can create professional-quality prints with perfect color changes, clean surfaces, and solid internal structures.

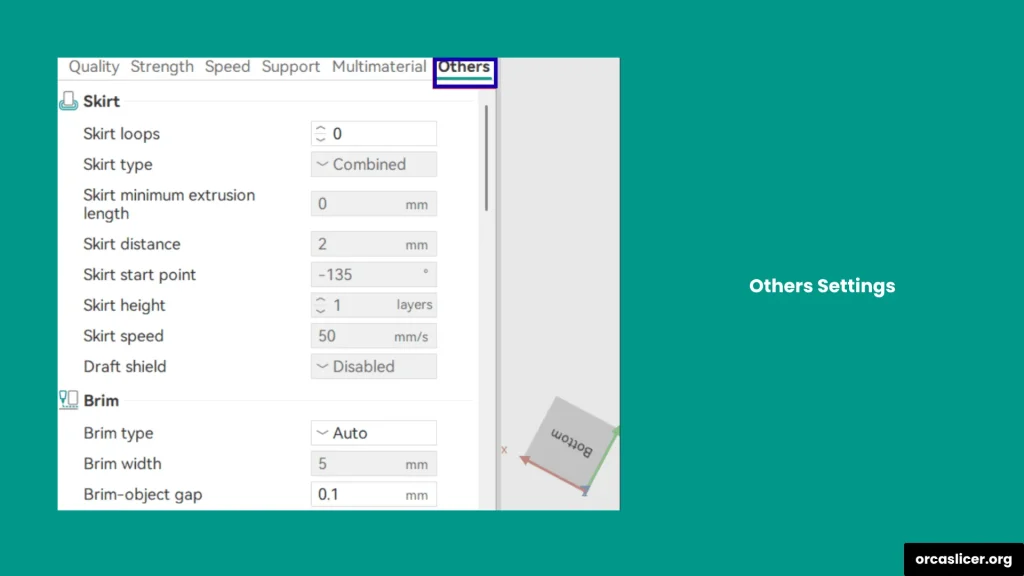

Others Settings

In Orca Slicer, the Others section contains a group of extra but very useful settings that give you more control over the overall printing process. These options let you fine-tune small details like skirt, brim, special modes, surface textures, G-Code output, and post-processing scripts.

Each of these features affects how your print starts, looks, and behaves once the file is sent to the printer. Let’s explore each option in detail.

Skirt

A Skirt is a line or loop that prints around the base of your model but does not touch it. It is printed before the main object starts. The main purpose of a skirt is to prime the nozzle and make sure the filament flows smoothly before printing begins.

In Orca Slicer, you can customize skirt settings such as number of loops around the model, distance from the object, height and thickness of the skirt lines. By adjusting these settings, you can stabilize filament flow, check the bed leveling, and ensure that extrusion starts cleanly. This is especially helpful when printing large or delicate models where the first layer quality is critical.

Brim

A Brim is a thin, flat layer printed directly around the base of your model, and unlike a skirt, it touches the model’s first layer. The brim improves bed adhesion, especially for parts with small contact areas or sharp corners that might lift during printing.

In Orca Slicer, you can modify:

- Brim width to decide how far it extends from the model.

- Number of lines in the brim.

- Layer height and spacing.

A wider brim gives your print more grip and helps prevent warping. After printing, the brim can be easily peeled off. It is one of the simplest ways to make sure your print stays firmly attached to the bed throughout the process.

Special Mode

The Special Mode section includes settings that let you control unique slicing and printing behaviors. You can adjust how layers are processed, how the printer moves, and even enable Spiral Vase Mode for continuous single-wall prints.

Key options include Sequential printing order ,Spiral Vase Mode and Layer height adjustments.These modes are useful for artistic or special-purpose prints where the standard print style does not fit your design needs.

Fuzzy Skin

The Fuzzy Skin setting lets you add texture to your 3D model’s surface. Instead of printing smooth walls, the printer moves slightly in and out to create a rough or bumpy look. This setting can hide small defects and give your print a unique, textured finish.

You can adjust:

- Fuzziness distance to define how deep the texture goes.

- Fuzziness density to control how close the rough patterns are.

- Surface selection (apply fuzzy skin to all surfaces or only outer walls).

Keep in mind that fuzzy skin adds extra print time since the printer moves more to create the texture. It is best used for decorative models or designs that benefit from a tactile surface.

G-Code Output

TG-Code Output settings control how your printer’s instruction file (G-Code) is created. These files tell your printer exactly where to move, when to extrude filament, and how fast to print.

In Orca Slicer, you can adjust the file formatting and compatibility for different printer types , start and end G-Code scripts and file compression and output location.Proper G-Code setup helps your printer run smoothly, prevents unexpected behavior, and ensures compatibility with your hardware. It also affects file size, readability, and performance during printing.

Post Processing Scripts

The Post Processing Scripts feature allows you to run custom commands after your G-Code file has been generated. This is useful if you want to add special instructions, automate tasks, or customize printer behavior before printing starts.

You can use it to Insert custom commands for cooling or heating ,trigger printer functions like pausing or bed leveling and run scripts that prepare the file for remote printing systems.

For example, you can make a script that automatically renames files, adds a pause for color changes, or moves the print head away from the bed after finishing a job.

Notes

The Notes section is a simple but very handy feature. It lets you write down important reminders, settings, or custom parameters inside your project file. These notes are saved as comments in the G-Code, so you can always refer to them later.

You can use this section to record:

- Which filament you used.

- Bed temperature or nozzle settings.

- Custom modifications or printing tips for a specific model.

This makes it easier to reproduce the same results in future prints and share details with other users.

Prepare

Before starting any 3D print, it’s important to prepare your model correctly. The Prepare section in Orca Slicer helps you set up your files and make sure they are ready for slicing and printing. Taking the right steps at this stage saves you time, improves print quality, and prevents common printing errors.

This is where you check the model’s orientation, scale, size, and structure. It also allows you to fix small geometry issues that might affect slicing. Whether your model is simple or complex, preparing it properly ensures the print begins smoothly and finishes successfully.

STL Transformation

In Orca Slicer, most 3D models are printed using STL files. These files store the surface geometry of your model and are easy for the slicer to process.

If you have STEP files (usually used in engineering and CAD programs), you can convert them into STL format directly within Orca Slicer. This conversion step is called STL Transformation.

Why STL Transformation is Important

- Improves slicing speed because STL files are lighter and easier for the slicer to handle.

- Increases compatibility as most 3D printers read STL files directly.

- Enhances print quality.

Tips for Better Results

- Use the correct resolution during conversion to keep fine details visible.

- Make sure your model’s scale and units are accurate after transformation.

- Always preview the STL file before slicing to confirm that no parts are missing or distorted.

Once your model is converted to STL, you can move on to positioning it on the print bed, adjusting supports, and setting print parameters confidently.

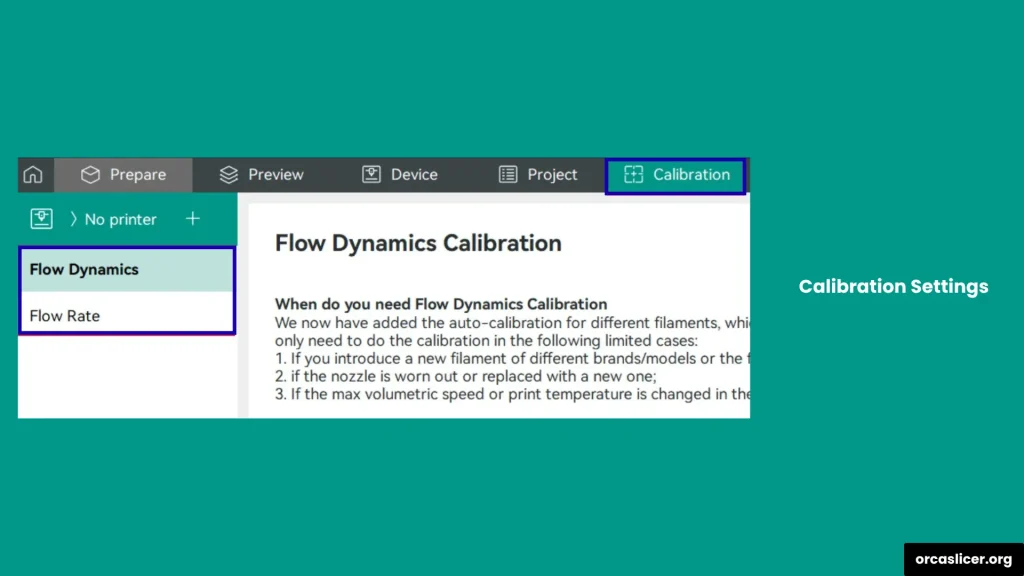

Calibrations

The Calibration Guide in Orca Slicer is where you learn to fine-tune your printer for the best performance. Proper calibration ensures that every part of your print comes out accurate, smooth, and strong.

By following these calibration steps, you can fix issues like stringing, over-extrusion, warping, and uneven layers. Once your printer is correctly calibrated, every print will look better and perform more reliably.

Let’s go through each calibration setting in detail.

Temperature

Temperature calibration is one of the most important steps in 3D printing. The right temperature ensures your filament melts evenly, sticks properly, and forms clean layers.

In Orca Slicer, you can adjust the Nozzle temperature, Bed temperature, Tower temperature and Segment temperature.If the temperature is too high, your print may have blobs or stringing. If it’s too low, the layers may not stick together. Always test with small calibration towers to find the best temperature range for each filament type.

Flow Rate

The Flow Rate setting controls how much filament the printer pushes through the nozzle. Getting this right is essential for strong, accurate prints.

A low flow rate causes gaps or weak infill, while a high flow rate creates bulging walls and over-extrusion. In Orca Slicer, you can run a flow rate calibration test to find the perfect balance.

Adjusting your flow rate correctly helps you achieve smooth surfaces, precise details, and strong layer adhesion.

Pressure Advance

Pressure Advance helps balance the pressure inside the nozzle during extrusion. When your printer moves quickly or changes direction, pressure inside the nozzle can fluctuate, causing uneven extrusion or blobs at corners.

This setting makes the filament flow consistent by adjusting the timing of extrusion and movement. As a result, corners become sharper, small features are cleaner, and you avoid oozing during fast direction changes.

Adaptive Pressure Advance

The Adaptive Pressure Advance setting automatically adjusts pressure changes during printing. It continuously monitors how the tool head moves and modifies the flow rate, acceleration, and bridging to keep the print smooth.

This dynamic adjustment helps avoid small defects caused by speed changes and makes your printer perform more consistently across all layers.

Retraction

Retraction pulls the filament back slightly into the nozzle whenever the print head moves across empty areas. This prevents unwanted strings or blobs between parts of your model.

In Orca Slicer, you can control the Retraction distance, Retraction speed, and Extra prime amount. Running a retraction test helps you find the perfect balance. Proper retraction settings give you clean prints without thin threads or leaking material.

Tolerance

Even when using the same filament and print file, different printers can produce slightly different results. The Tolerance setting allows you to fine-tune these small variations.

This feature helps you adjust for differences in nozzle size, filament diameter, and printer mechanics. Calibrating tolerance ensures that parts fit together properly, especially for mechanical or interlocking models.

Advanced Calibration

Once you have basic calibration done, Advanced Calibration helps you fine-tune more complex print behaviors. These include parameters that affect how your printer handles speed, vibration, and sharp corners.

Let’s discuss them one by one:

Volumetric Speed

This setting controls how fast your printer can push out filament without clogging the nozzle. A proper volumetric speed prevents under-extrusion, blobs, and uneven layers. Slower speeds create smoother prints, while faster speeds are great for larger, less detailed parts.

Cornering (Jerk and Junction Deviation)

Cornering settings adjust how your printer handles turns and direction changes. Proper calibration keeps corners sharp without shaking or ringing marks. Tuning Jerk and Junction Deviation helps your printer move smoothly and maintain consistent quality even at higher speeds.

Input Shaping

Input Shaping reduces vibration and ringing marks that often appear on the surface when printing at high speeds. This feature compensates for motion errors by controlling how the print head accelerates and decelerates. With the right input shaping settings, your prints will have cleaner surfaces and better detail.

VFA (Vertical Fine Artifacts)

VFA stands for Vertical Fine Artifacts, which are tiny imperfections that appear as wavy lines on vertical surfaces. Orca Slicer has built-in VFA control settings to minimize these artifacts and improve the smoothness of your walls and corners.

Proper calibration removes these marks and gives your prints a flawless, professional finish.

Orca Slicer provides a complete set of calibration tools that make your printer more reliable and your prints more beautiful. From temperature and flow to vibration and fine detail, each calibration step improves how your printer performs in real-world conditions.

Take your time to test each setting using small calibration models, note the results, and adjust gradually. Once everything is tuned perfectly, your printer will deliver top-quality prints every single time.

Proper calibration removes these marks and gives your prints a flawless, professional finish. Orca Slicer provides a complete set of calibration tools that make your printer more reliable and your prints more beautiful. From temperature and flow to vibration and fine detail, each calibration step improves how your printer performs in real-world conditions.