Walls and Surfaces

In Orca Slicer, the Walls and Surfaces settings help you improve your 3D print quality by controlling how the outer and inner walls are printed. These settings let you fine-tune the surface finish based on your model’s design and printing needs.

When working with wall settings in Orca Slicer, one of the most important things is selecting the right wall printing order. If you choose it correctly, your 3D model will have stronger layers and a smoother surface finish. This single setting can make a big difference in print quality and appearance.

Walls Printing Order

In Orca Slicer, the wall printing order decides how your printer builds the inner and outer walls of a 3D model. Changing this order can affect both the strength and the surface quality of your print. Let’s look at each option and see what it does.

Inner/Outer

When your model has overhangs or angled parts, choosing Inner/Outer as the print order helps the layers stick better. The inner wall prints first, then the outer wall follows.

This setting gives you stronger support and stability, but the surface quality might drop a little. The reason is that the inner wall slightly pushes against the outer wall, which can cause minor surface deformation.

Inner/Outer

Inner/Outer/Inner

The Inner/Outer/Inner print order focuses on surface finish and precision. Since the outer wall is printed between two inner walls, it gets a cleaner, smoother, and more accurate look.

However, this setting isn’t ideal for overhangs, because the outer wall prints before any internal support. You can only use this option when your print has at least three wall lines.

Inner/Outer/Inner

Outer/Inner

With Outer/Inner, you’ll get a high-quality surface and great dimensional accuracy, similar to the previous option. But one downside is a visible or uneven Z-seam, since the first layer of extrusion appears on the model’s surface. This setting is often used when you want your print to look perfect from the outside and don’t mind a small seam.

Outer/Inner

Print Infill First

Infill is the internal support structure that makes your print solid. When you enable Print Infill First, the slicer prints the infill, top, and bottom layers before the walls. This setting helps with overhangs and supported designs, but it can slightly push the outer walls outward when the infill cools and expands.

Print Infill First

To avoid this, combine it with:

- Precise Wall mode

- Inner/Outer/Inner wall order

- A reduced infill/wall overlap

These adjustments help prevent infill pressure from deforming the outer wall, giving your model both strength and a smooth finish.

Wall Loop Direction

In Orca Slicer, the Wall Loop Direction controls the direction in which your printer moves while printing the walls when viewed from the top. By default, all wall loops are printed anticlockwise, unless you enable the Reverse on Even option. If you manually select a wall direction instead of keeping it on “Auto,” the printer will follow that direction, unless Reverse on Even is turned on.

Note: When printing vase mode or spiral prints, this setting is automatically disabled because the model uses a continuous outer wall instead of separate loops.

Choosing the right wall loop direction helps you get consistent extrusion, better surface accuracy, and smooth transitions between perimeters.

Surface Flow Ratio

The Surface Flow Ratio setting in Orca Slicer decides how much filament is used to print the top and bottom solid layers. Adjusting this value slightly can improve your print’s surface finish and prevent over-extrusion.

A lower surface flow ratio (for example, slightly below 1.0) can result in smoother top surfaces with fewer blobs or uneven lines. The final surface flow is calculated by multiplying your surface flow ratio by your filament flow ratio.

Tip: If you’re not using the default value of 1.0, make sure to calibrate your flow rate properly first. Correct calibration ensures accurate extrusion and prevents rough or uneven top surfaces.

Only One Wall Settings

The Only One Wall option is designed for models that have flat or narrow surfaces. This setting helps create more room for the top infill pattern, giving you a smoother finish on small prints.

It’s especially useful for small details or text-based prints, such as letter engravings or tiny flat areas, where using multiple walls can crowd the infill and reduce coverage. By printing only one wall, the infill pattern gets enough space to fill the surface evenly.

However, for larger models or parts that need strength, this option isn’t recommended since one wall provides less structural support.

Only One Wall

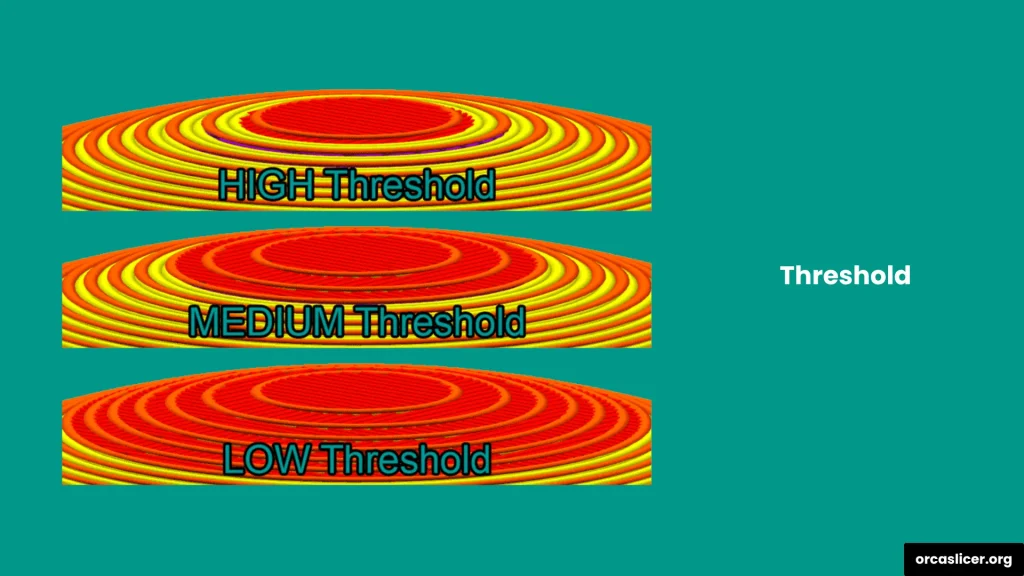

Threshold

The Threshold setting defines the minimum width for printing top layers. If a top surface is smaller than the threshold value and partly covered by another layer, the printer will skip it to prevent unnecessary printing.

You can set the threshold value either in millimeters (mm) or as a percentage of the perimeter extrusion width. This helps you fine-tune how thin or small top layers should be before they are ignored.

Note: When printing narrow surfaces or small designs (like letters or fine textures), this setting may sometimes create unwanted gaps or small print artifacts. To avoid this, set the value to zero to disable the threshold for such prints.

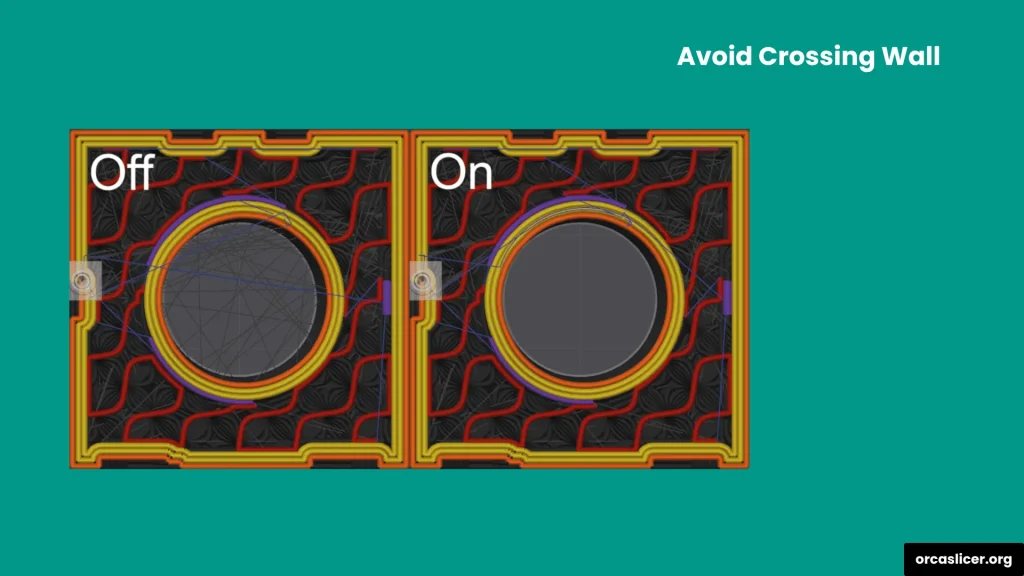

Avoid Crossing Walls

The Avoid Crossing Walls setting helps your printer move smartly so the nozzle doesn’t pass over or overprint any walls. Instead, it makes a small detour before starting the next wall, keeping the nozzle path clean and well-aligned during travel moves.

This setting improves surface quality by preventing marks or scratches caused when the nozzle crosses printed areas. Although it may slightly increase print time, the final finish becomes much smoother and cleaner especially on visible surfaces.

If you’re printing flexible or sticky materials like PETG or TPU, this feature becomes even more useful. It helps reduce stringing and keeps the print surface looking neat. Professional users often enable this option when printing detailed or aesthetic models that require a perfect finish.

Max Detour Length

The Max Detour Length setting defines how far the printer’s nozzle can travel to avoid crossing a wall or perimeter. You can adjust this value in three different ways depending on your needs:

- Absolute Value (in mm): Set a specific distance in millimeters to control how far the nozzle moves before starting the next wall.

- Percentage Value: Choose a percentage value based on the direct travel path distance. This gives you more flexibility for different model sizes.

- Value Set to “0”: Setting the value to zero removes the limit, allowing the printer to take any detour length needed to avoid crossing walls.

Keep in mind that larger detour values mean longer print times, but they greatly reduce or eliminate wall crossovers. Find a balance that works best for your print speed and surface quality goals.

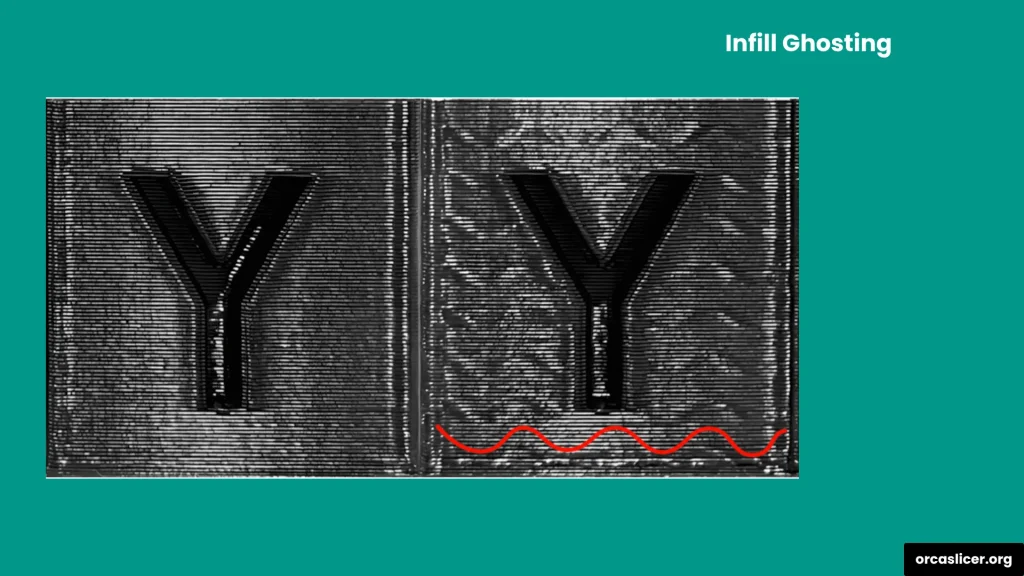

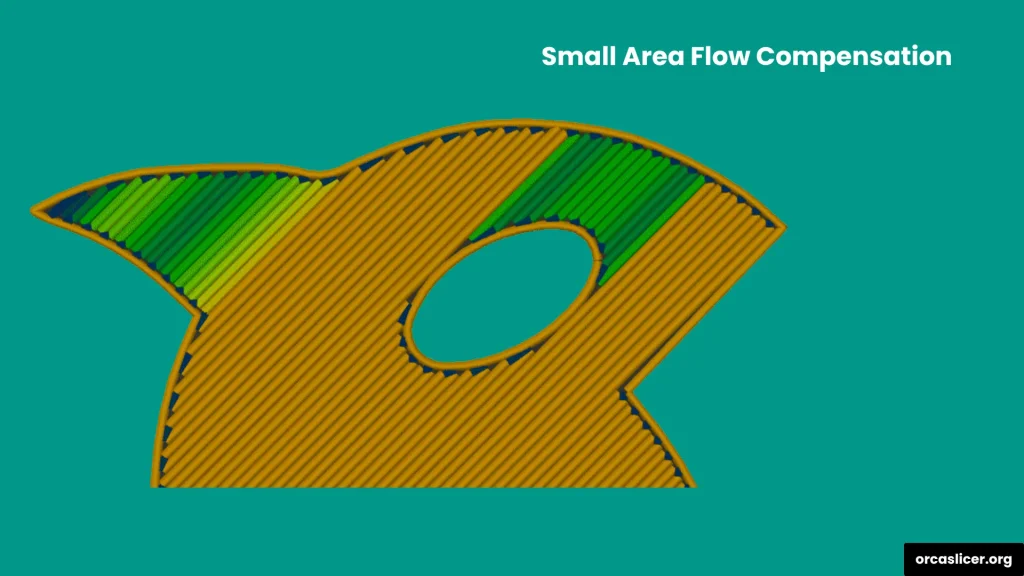

Small Area Flow Compensation

The Small Area Flow Compensation setting helps improve print quality in tiny or narrow areas, such as the top layers of letters or fine surface details. When you enable this feature, the slicer automatically adjusts the extrusion flow to match the limited print space.

Without this setting, using a standard flow rate in small areas can cause over-extrusion, uneven layers, or rough surfaces because too much filament is being pushed into a very small space. By enabling adaptive flow control, the printer reduces the flow rate just enough to create smooth, detailed surfaces without extra filament buildup.

This setting is ideal for models that include fine text, logos, or decorative patterns, where surface detail matters more than print speed.

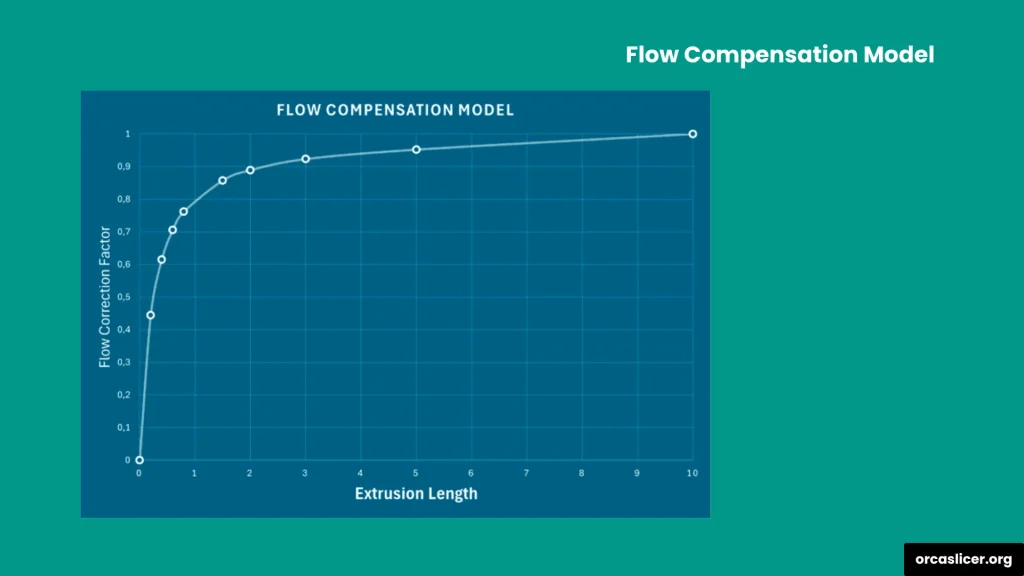

Flow Compensation Model

The Flow Compensation Model controls how the software adjusts extrusion flow in relation to the extrusion length. It uses a linear interpolation method, meaning the slicer automatically calculates how much filament should be extruded based on the length of the printed line and a flow correction factor.

In simple terms, the slicer creates a set of paired values that link the extrusion length to the correct flow rate. This ensures consistent extrusion, especially in areas where lines start, stop, or overlap, helping maintain perfect layer smoothness across small and detailed parts.