Single Extruder Multimaterial Printing

Single extruder multi-material printing means using different filament materials through a single nozzle or extruder. It can be a bit challenging because you have to make sure that all materials work together in perfect alignment during the printing process.

For Orca Slicer users, the setup is very similar to Prusa Slicer, as both share the same base functionality. However, Orca Slicer includes extra features and flexible settings that make multi-material printing easier and more precise than Prusa.

In this guide, we will explain each step clearly so you can understand how to configure your multi-material settings in Orca Slicer and achieve consistent, high-quality results without complications.

Prime Tower

The prime tower is the first structure created during multi-material 3D printing. It acts as a support area where the printer purges old filament before switching to a new one, ensuring smooth transitions and clean color changes. This structure is essential for preventing oozing, stringing, wrapping, or bulging during material shifts.

By customizing your prime tower settings, you can control its width, shape, and size according to your print requirements. Setting these parameters correctly helps maintain stable printing conditions and prevents surface defects.

Settings

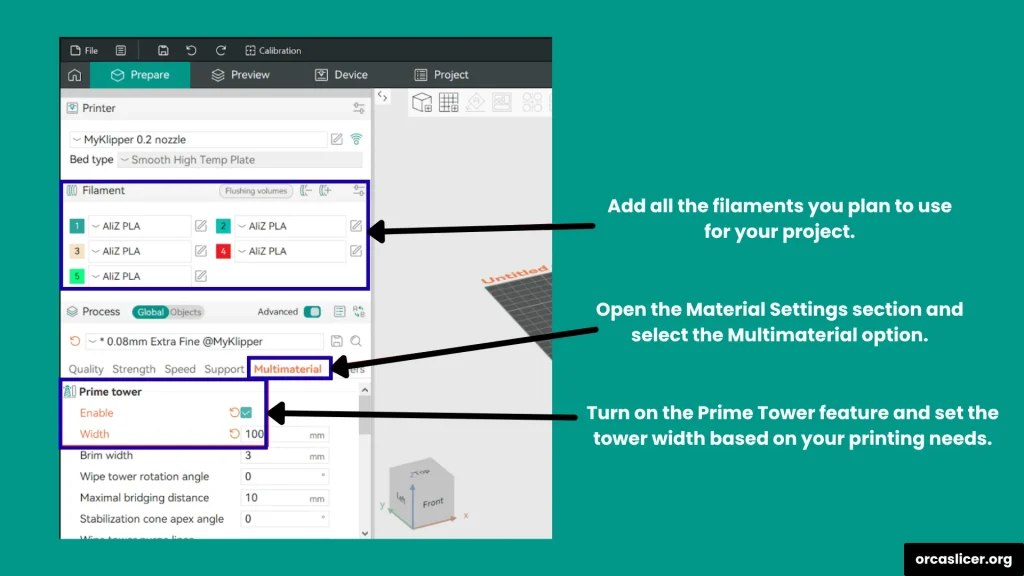

- Open Orca Slicer and go to Material Settings.

- Select the Multimaterial option.

- Click on the Filament Tab, add the number of filaments you plan to use, and select their types.

- Open the Multimaterial Tab in the second menu and enable Prime Tower.

- Choose the Prime Tower width from the options box.

- Tap into the Advanced Settings to access more parameters, such as: Brim Width, Wipe Tower Rotation Angle, Maximal Bridging Distance, Stabilization Cone Apex Angle, Wipe Tower Purge Line and other customization values are shown in Orca Slicer’s interface.

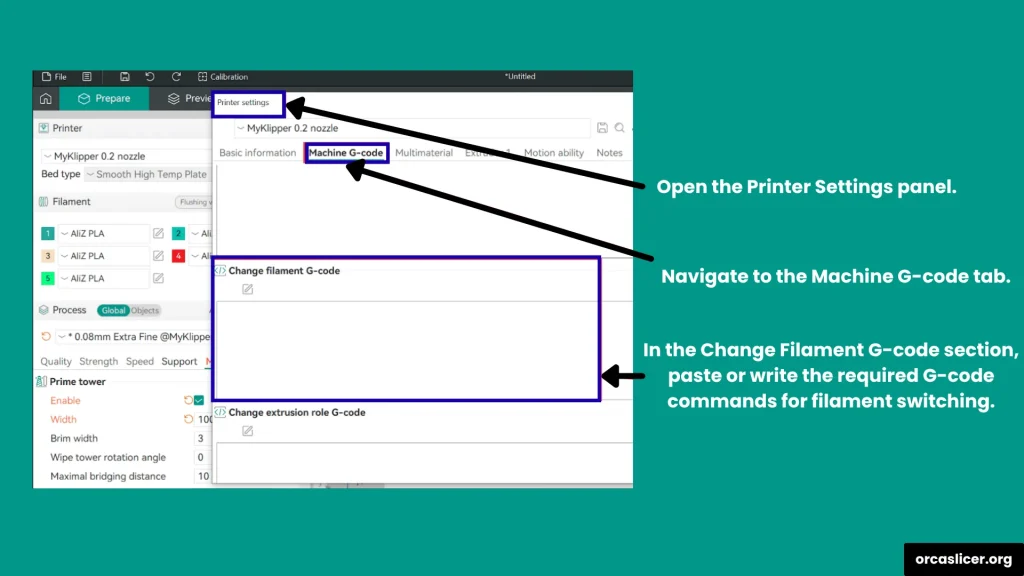

Once your prime tower and filament settings are ready, move to the Printer Settings tab:

- Open the G-code Machine Tab and scroll down to find the Change Filament G-code section.

- Add the commands based on your printer’s firmware:

Marlin: Use the M600 command to trigger filament changes.

Klipper: Create a custom M600 macro or use commands like PAUSE to unload and load new filament.

If you prefer a simple, universal setup, type “PAUSE” in the G-code box and save your settings. This allows your printer to pause automatically whenever a filament change is required.

Once everything is set, you can slice your multi-material print, save the configuration, and start printing. With these optimized prime tower settings, Orca Slicer ensures clean transitions, steady extrusion, and top-quality results for all your multi-material projects.

Ramming

In simple terms, ramming is the process of pushing the filament through the nozzle before extrusion begins, ensuring that it flows at the correct speed and temperature. This step helps the printer prepare the filament for a smooth and consistent material transition, especially during multi-material or color changes.

In the latest versions of Orca Slicer (2.3.0 and above), the ramming process is a built-in automated feature, so you don’t need to adjust or manually configure it. The slicer automatically handles the filament pressure and flow, maintaining the perfect balance for clean and precise printing results.

Manual Filament Change

A manual filament change is one of the most common and useful features in 3D printing. It allows you to switch filament colors or materials while printing, giving you more creative control over your design. Most slicers, including Orca Slicer, provide built-in G-code settings that automatically pause the printer, allowing you to load a new filament or replace an empty spool before resuming the print.

This function is perfect for multi-color 3D printing or when you want to combine different filament types in a single project.

Settings

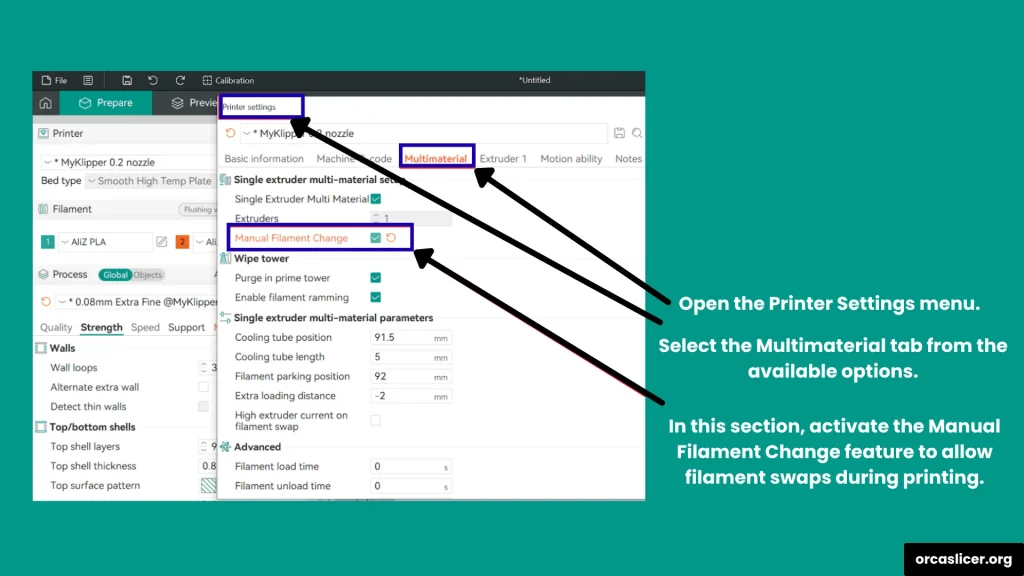

- Open Orca Slicer and go to the G-code Machine Settings tab.

- Find the Filament G-code Settings section.

- In the settings box, add either M600 or simply type PAUSE.

- Click Save Settings once you’re done.

Next, open the Multimaterial Settings tab and enable Manual Filament Change. After enabling this option, you can specify:

- The exact layer or position where the printer should pause.

- The distance and speed for the ramming process before the change.

- The timing for when the filament should be replaced.

Once configured, Orca Slicer will automatically pause at your chosen point, allowing you to swap the filament and continue printing seamlessly manually. This feature ensures smooth transitions, accurate color placement, and professional-quality multi-material prints.