Bridging Settings

In 3D printing, many models include parts known as bridges. These are horizontal sections that stretch across gaps or open spaces and are printed without supports underneath.

Printing bridges requires careful control because the filament has to span the gap while staying straight and smooth. Since there is nothing beneath to hold it, the printer must handle the speed, cooling, and extrusion flow with accuracy.

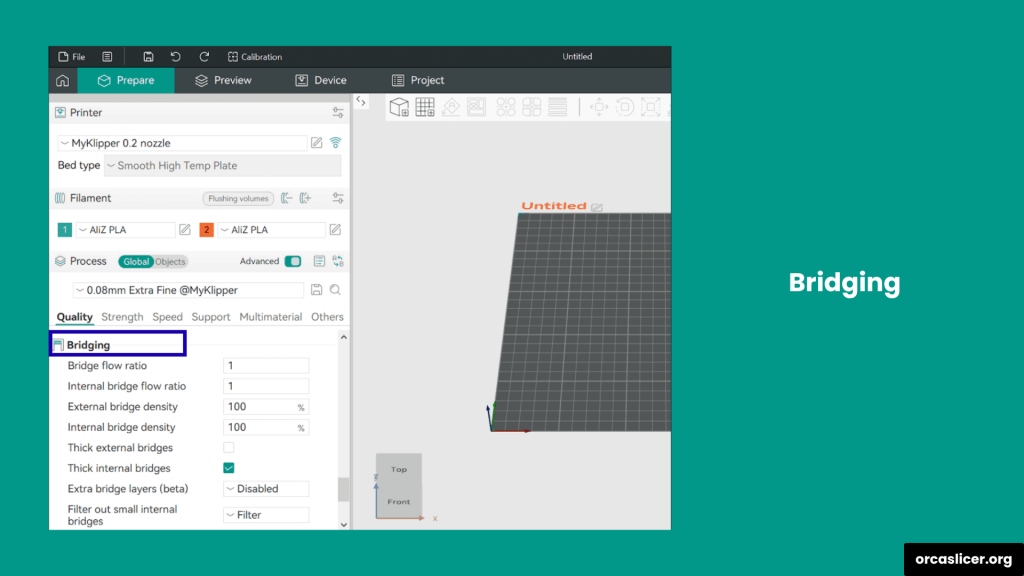

In Orca Slicer, the Bridging settings help you create strong bridges that look clean and do not sag. The slicer adjusts the flow rate, bridge speed, and cooling to make sure the filament stays tight until it reaches the other side and solidifies.

These settings are very useful for printing overhangs, gaps, and suspended layers where precision matters most. By optimizing the bridge parameters, you can improve both the strength and surface finish of the top layers.

Let’s now explore each bridging setting, understand how it works, and see how you can use it to achieve high-quality bridges in Orca Slicer.

Flow Ratio

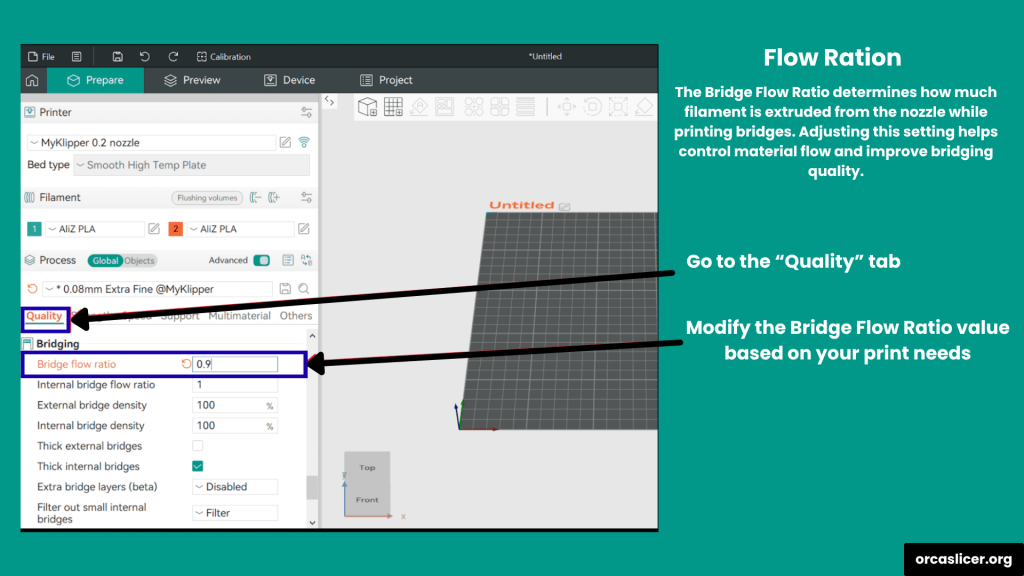

The Flow Ratio controls how much filament your printer releases during printing. It plays a key role in balancing material flow for better quality and cleaner bridges. If you notice that your filament is sagging or drooping while printing a bridge, you can slightly lower the flow ratio to reduce the amount of material coming out of the nozzle. This adjustment helps the filament stay tighter and prevents excess extrusion.

For example, setting the flow ratio to around 0.9 can make a big difference. The actual bridge flow ratio is calculated by multiplying your filament flow ratio (and your object’s flow ratio, if you have one set) by the value you choose here.

Bridge Flow Ratio

The Bridge Flow Ratio tells the printer to reduce extrusion while printing bridges. By lowering the amount of material, the filament stays straight and tight across the open gap instead of sagging. This setting is especially important when printing long or unsupported bridges, as it keeps the top layers clean, smooth, and free from drooping lines.

Bridge Density

Bridge Density setting controls how thick each bridge layer is printed above the infill or base structure of your 3D model. Adjusting this setting helps you manage the thickness and strength of the bridge while improving the overall print quality.

If the bridge layer looks too thick, rough, or uneven, it usually means that the printer is pushing out too much filament. To fix this, slightly lower the bridge density value so the printer extrudes less material. This adjustment results in a smoother and cleaner bridge surface.

The actual Internal Bridge Flow value is automatically calculated by multiplying the bridge density with the bridge flow ratio, filament flow ratio, and object flow ratio (if set). This ensures consistent control over the amount of material used for the bridge layer.

External Bridge Density

The External Bridge Density defines how closely the bridge lines are printed on the outer surface. By default, the value is 100 percent, which means the lines are solid and fully connected.

If you lower this value slightly, small gaps appear between the bridge lines. These gaps allow better air circulation, which helps the filament cool and harden faster. This results in cleaner bridges and reduced sagging, especially in long or detailed prints.

Internal Bridge Density

The Internal Bridge Density controls the spacing between the bridge lines inside the model. The default value of 100 percent means there is no gap between the lines, and the bridge is printed as a solid layer.

Lowering this value adds a little spacing between the internal bridge lines, improving airflow and cooling. This helps the internal bridge layers solidify evenly and reduces surface swelling. It is especially useful when you choose internal bridge structures instead of the regular infill pattern.

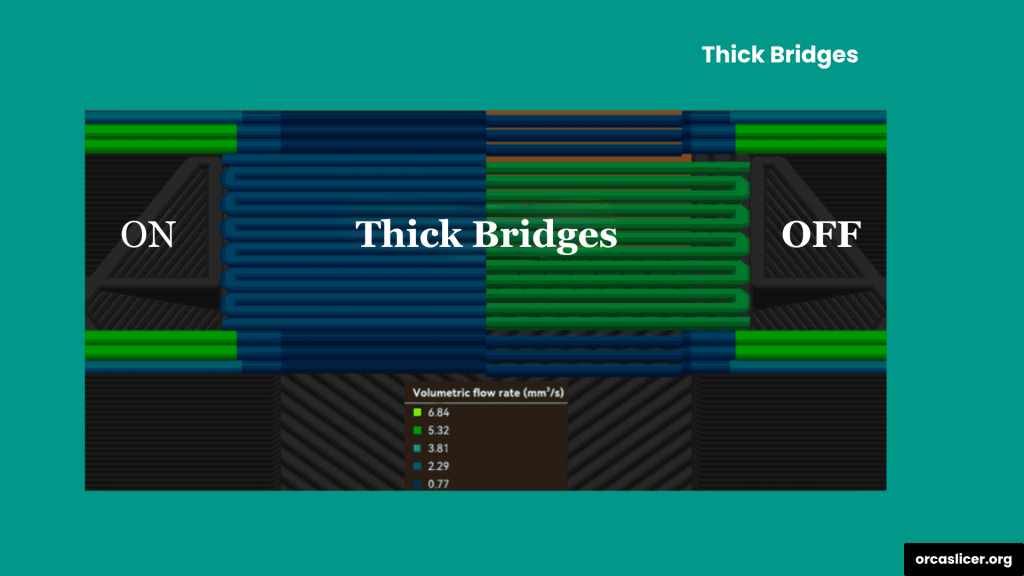

Thick Bridges

Thick Bridges settings help you control the strength and surface texture of both external and internal bridges. By adjusting these options, you can balance between visual quality and structural reliability depending on your model’s design.

Thick External Bridges

When you enable Thick External Bridges, the printer creates bridges that are denser and thicker, which increases their strength and durability. This setting is especially useful for long bridges, where extra support is needed to prevent sagging or breaking.

However, thicker external bridges can lead to a rougher surface texture. If your goal is a smooth and polished look, you can disable this option. Disabling it works best for short bridges or models where appearance is more important than strength.

Thick Internal Bridges

The Thick Internal Bridges option makes the inner bridge layers stronger and more reliable by increasing their thickness. Enabling this setting improves the internal structure’s stability and prevents the top layers from drooping.

For most models, enabling this option is recommended. However, if you are printing with a large nozzle diameter, it is better to keep this setting disabled, as the extra thickness can cause over-extrusion or uneven layering.

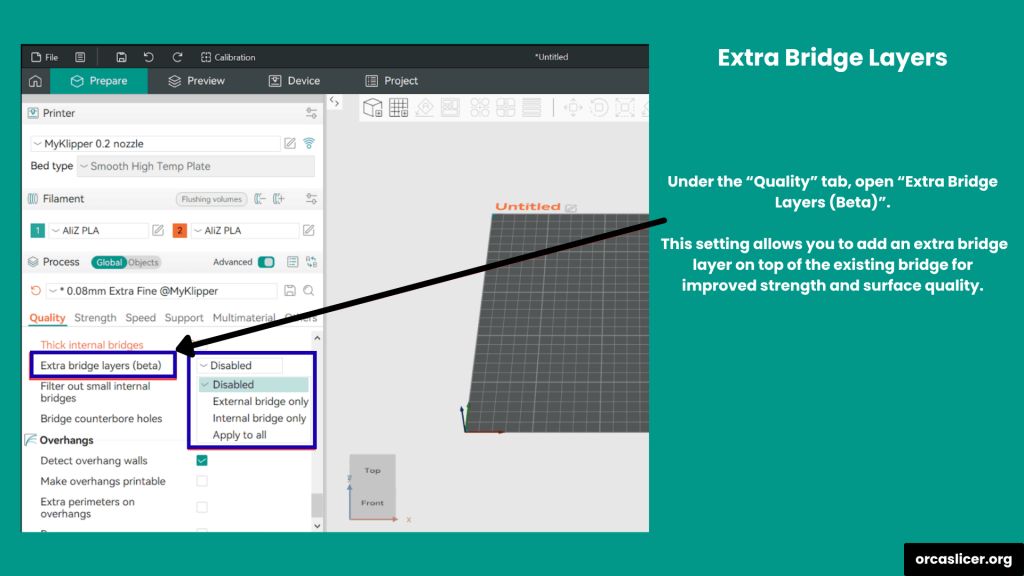

Extra Bridge Layers

In Orca Slicer, the Extra Bridge Layers setting allows you to add one or more additional layers on top of an existing bridge. This helps improve the surface finish, strength, and appearance of the bridge area, giving your print better stability and a smoother top surface.

When this feature is enabled, the printer adds an extra layer over the first bridge. Since the first bridge is printed across a gap, the added layer acts as extra support and enhances the overall structure. It also improves how the top infill bonds with the bridge, resulting in stronger and cleaner prints.

This option is especially useful for high-speed printers, where bridging speed differs from infill speed. Adding an extra bridge layer helps maintain quality even at faster print speeds.

Recommended: For most prints, it is best to enable External Bridge Only. You can choose other options if your model has specific design or strength requirements.

Options in Extra Bridge Layers

Disabled

Select Disabled if adding an extra bridge layer is not suitable for your model. When this is chosen, no additional bridge layers will be printed.

External Bridge Only

With External Bridge Only, the printer adds an extra layer only on the visible or outer bridge areas. This setting improves the look and smoothness of surfaces that are visible on the outside.

If a bridge is too small or thinner than the number of wall lines you have set, the slicer automatically skips it because an extra layer there would not make a noticeable difference.

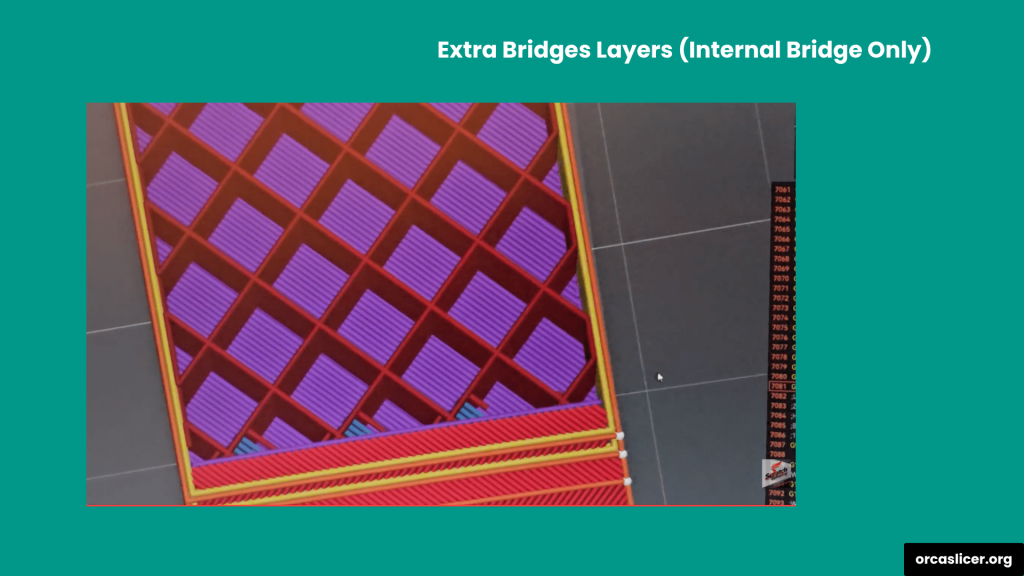

Internal Bridge Only

The Internal Bridge Only option lets the printer create a second bridge layer on internal bridge sections that are already printed above sparse infill. These extra layers become part of the top shell and are counted in the total number of top layers for your model.

The second internal bridge layer is printed almost at a right angle to the first one, forming a criss-cross pattern that increases overall bridge strength and prevents deformation.

In cases where a model contains bridges in multiple directions (also known as “islands”), Orca Slicer automatically uses the angle of the last bridge region in that island to decide the direction for the second layer.

Apply to All

Choosing Apply to All tells the printer to add the second bridge layer for both internal and external bridges. This gives the strongest support but may increase print time slightly.

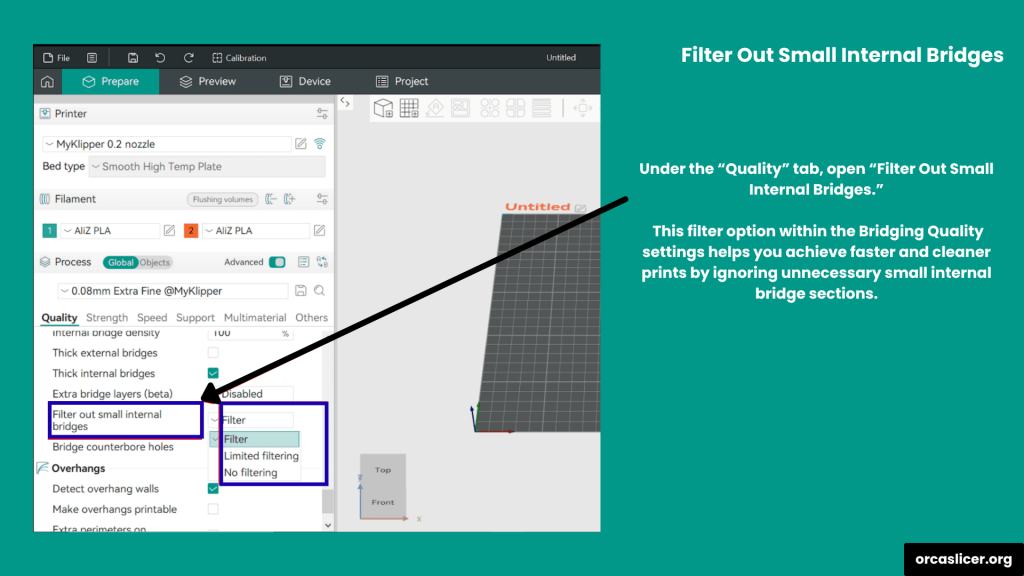

Filter Out Small Internal Bridges

The Filter Out Small Internal Bridges setting helps you avoid printing unnecessary internal bridges that can cause surface problems like pillowing. Pillowing happens when the top surface of your print becomes uneven or slightly swollen because of the unsupported infill underneath.

By default, Orca Slicer automatically filters out these internal bridges and only prints the solid top infill over the sparse infill. This makes printing faster and smoother while keeping the top layer clean and even.

This filter works very well for models with high infill density, but its behavior changes for models that are curved or heavily slanted. When printing such models with low infill density, unsupported areas can curl upward, creating pillowing. In these cases, allowing limited internal bridges can help add support and reduce surface deformation.

By adjusting the filter mode, you can control how sensitive Orca Slicer is when deciding whether to print or skip these small internal bridges.

Filter Modes and Their Uses

Filter

This is the default option and filters out all internal bridges. It works perfectly for most 3D printing situations and provides a good balance between speed and quality.

Limited Filtering

This allows the printer to create internal bridges only in specific areas that truly need extra support, such as curved or slanted parts of a model. This option prevents unnecessary bridges while still improving the strength of complex designs. It is ideal for difficult or detailed prints that require controlled support.

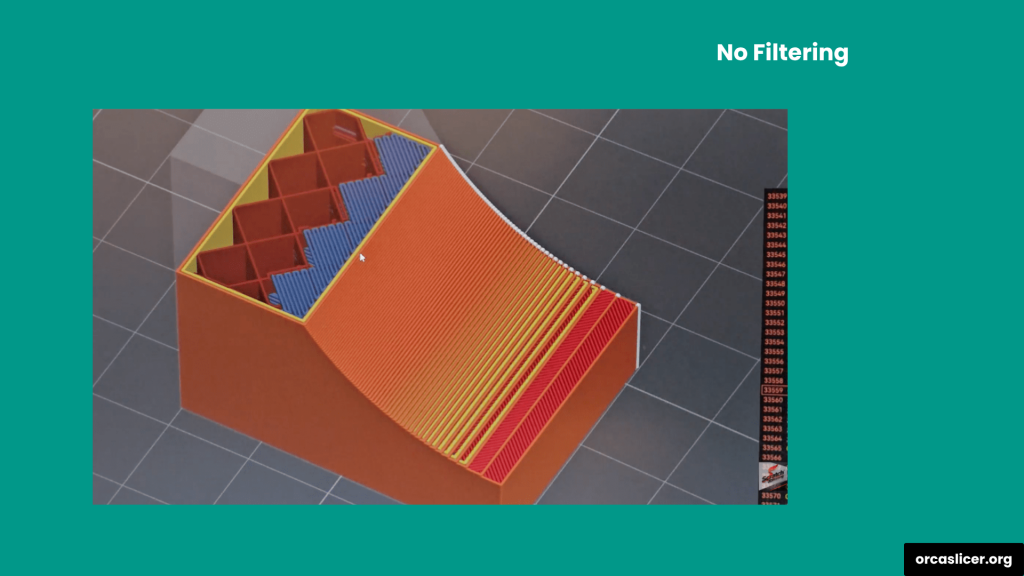

No Filtering

It tells the printer to generate internal bridges everywhere, even in small or heavily slanted regions. This ensures maximum support but also increases print time and material usage. It is best used for extreme overhangs or curved top surfaces where skipping bridges is not possible.

In simple words, the difference between these modes is how strict Orca Slicer is when deciding to add or skip internal bridges. Choosing the right filter mode helps you get a perfect balance between print quality, speed, and material efficiency.

Filter Modes and Their Uses

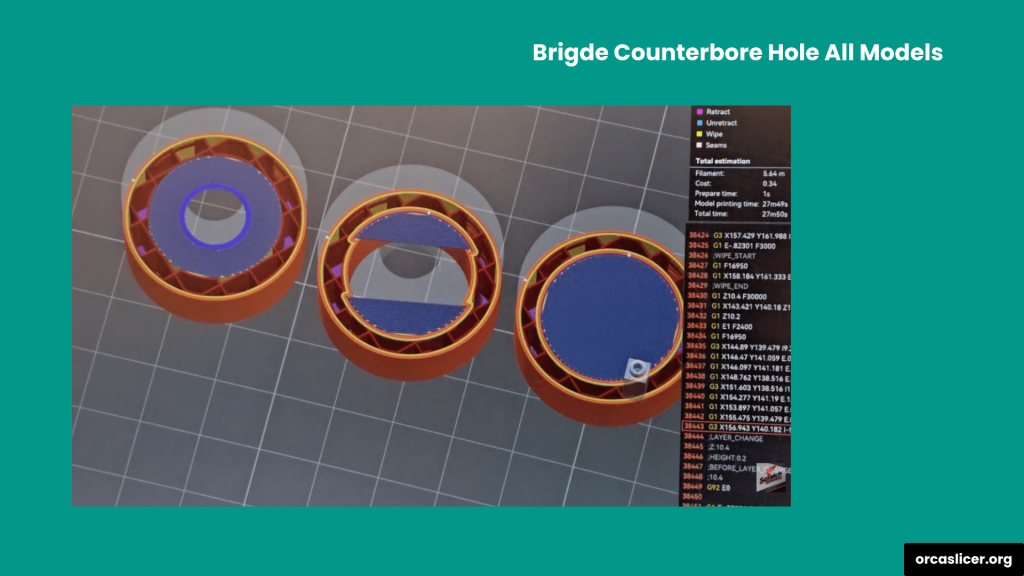

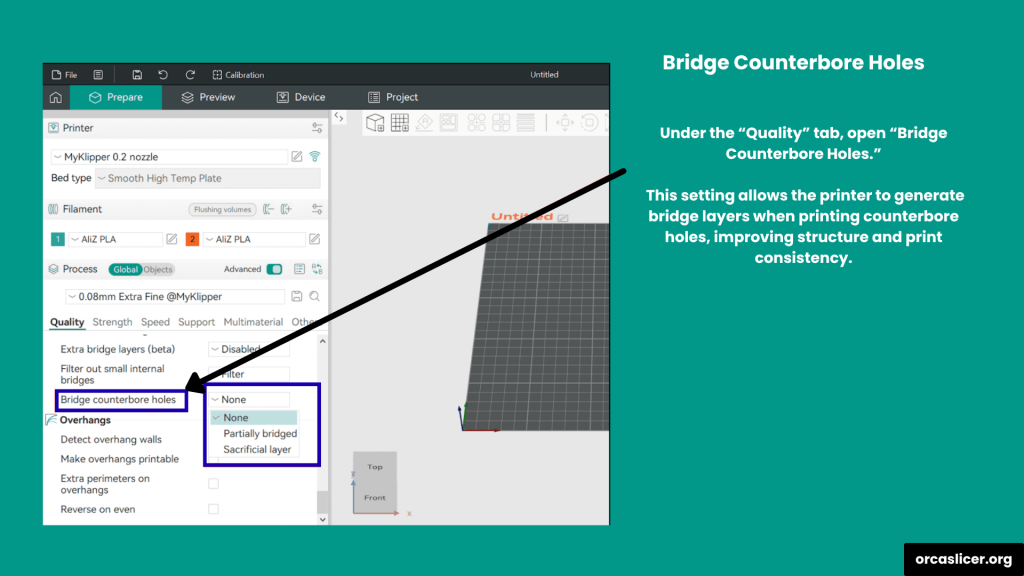

The Bridge Counterbore Hole setting helps you print clean and accurate holes without using supports or overhangs. When this setting is turned off, printing a counterbore hole can cause problems like sagging, missing perimeters, or uneven surfaces.

This feature is available under the Bridge category in the Quality settings section. It allows your printer to create temporary bridge layers while printing counterbore holes. These bridge layers act as a base for the next layers to form correctly and can easily be removed after printing.

Using this option helps you achieve high-quality counterbore holes with smooth edges and minimal surface deformation, even when no support structures are used.

Bridge Counterbore Hole Options

None

This option prints the counterbore hole without any bridging. It is not recommended because it often results in surface defects, uneven layers, and incomplete edges.

Partially Bridged

The Partially Bridged option adds partial bridge layers on both sides of the counterbore hole. These partial supports help the printer create the next layer or perimeter more precisely and reduce sagging.

Sacrificial Layer

When you select the Sacrificial Layer option, the printer creates a complete temporary bridge layer across the hole. This layer supports the upcoming print layers and ensures a perfectly formed counterbore hole. Once printing is finished, you can remove or break this temporary bridge layer easily.