Pellet Flow Coefficient

The pellet flow coefficient measures how densely the material is packed and extruded through the nozzle during 3D printing. It depends on two main factors, i-e, the feeding mechanism of the printer and the speed at which the pellets are pushed out of the nozzle.

Unlike filament-based printing, which relies on fixed filament sizes and volume calculations, pellet printing uses this empirical flow coefficient to determine the correct amount of material extrusion. The coefficient varies depending on the shape, size, material type, and density of the pellets being used.

If you are switching from filament printing to pellet printing, it’s important to understand that while the process is similar to FDM printing, the settings are not identical. Pellet printing focuses on adjusting the flow rate and feed calibration instead of relying on filament diameter or extrusion volume.

In Orca Slicer, you can fine-tune the pellet flow coefficient to match your printer’s hardware and material type. Setting the right value ensures accurate extrusion, consistent layer deposition, and high-quality large-format prints without material waste or uneven flow.

Understanding the Pellet Flow Coefficient

Printers that can print objects larger than 1m³ are called Large Format Printers, and instead of using filaments, they work with pellets. Technically, the printing process is very similar to Fused Deposition Modeling (FDM), but the difference lies in the material feeding method.

In traditional 3D printing, we use the filament diameter to calculate the material volume required for extrusion. However, in pellet-based printing, this is replaced by the pellet flow coefficient, which measures the material’s packing density and determines how much material is extruded per turn of the feeding mechanism.

Pellet Flow Coefficient

The pellet flow coefficient represents how tightly the pellets are packed inside the extruder and how much material they produce during printing. It helps in calculating the input volume of the pellets being used.

Packing Density

Packing density depends on three main factors:

- The shape of the pellets.

- The density of the material.

- The type of material used.

These properties affect how much material is extruded in each turn of the feeder. A higher packing density means more material is extruded per cycle, while a lower density results in less material flow.

Relationship Between Pellet Flow Coefficient and Filament Diameter

You can convert the pellet flow coefficient into an equivalent filament diameter using a simple mathematical relation. The square root function shows how the linear volume relates to the flow coefficient.

If your material has a higher packing density, it will extrude more material in one turn, effectively behaving like a larger filament diameter. In simpler terms, a higher pellet coefficient equals greater extrusion output, assuming all other slicer parameters remain constant.

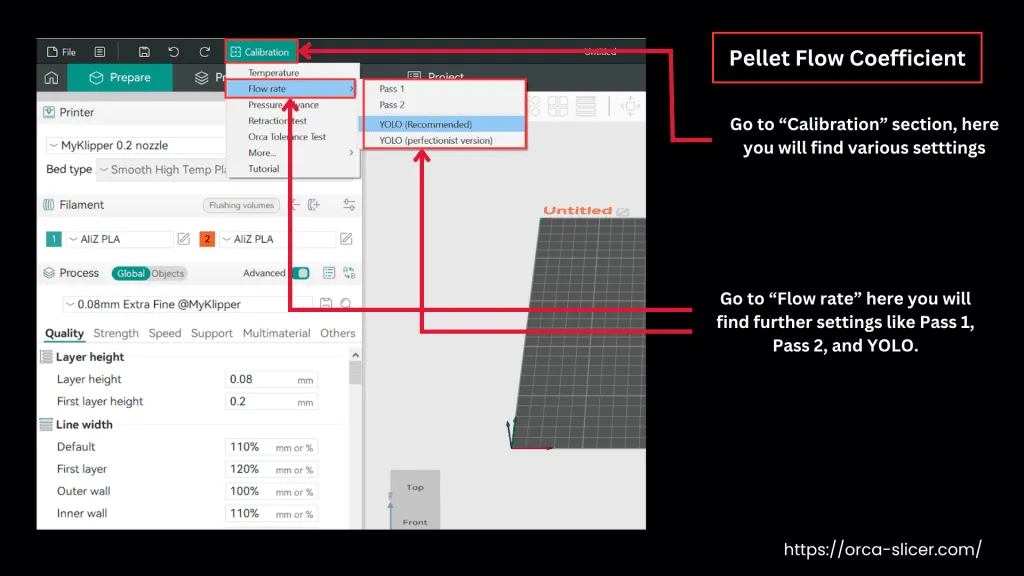

Calibration in Orca Slicer

Orca Slicer includes a built-in calibration tool that allows you to fine-tune printing parameters such as temperature, flow rate, and pellet volume. You can enter your flow coefficient, experiment with temperature and speed, and calculate the exact volume needed for your print.

Additional Settings

- Flow Ratio: Indicates the amount of material being extruded during printing. Adjusting this helps you control flow consistency and layer bonding.

- Pass 1 and Pass 2: Represent multiple extrusion passes used to refine the print surface and improve accuracy.

- YOLO Mode: Allows you to use a single pellet material at different flow rates, depending on your project’s requirements. It provides flexibility for testing and optimizing large-scale prints.

By understanding and configuring the pellet flow coefficient properly, you can achieve accurate extrusion, smooth surface finishes, and efficient material usage for all your large-format 3D printing projects in Orca Slicer.