Layer Height Settings

In 3D printing, getting a successful print is easy, but maintaining consistent print quality requires precise control over your settings. With Orca Slicer, you can easily manage print quality using its built-in configuration options designed for accuracy and performance.

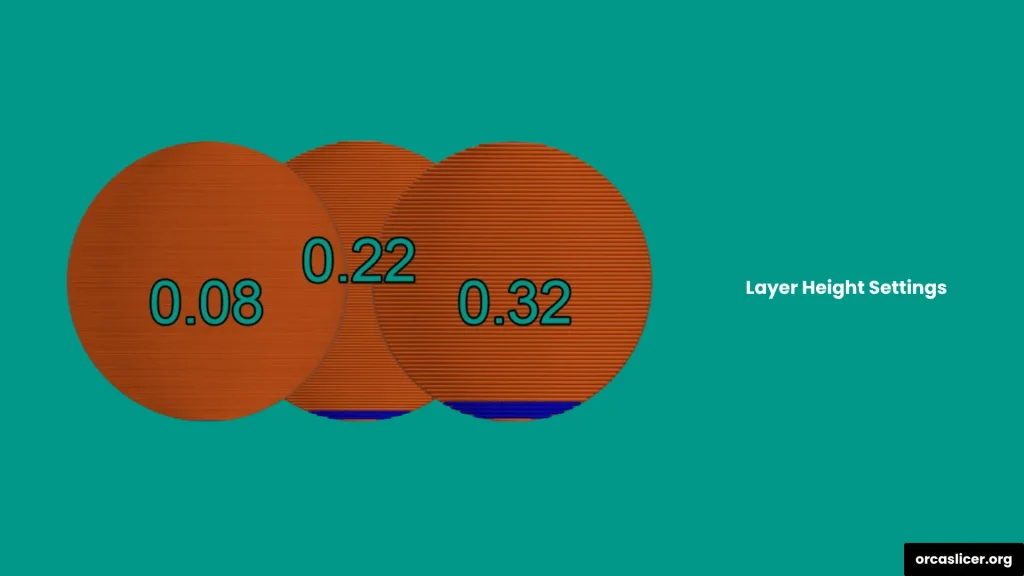

One of the most important factors in quality control is the layer height. It defines the vertical thickness of each printed layer during a single pass of the nozzle. This parameter directly affects both the printing speed and the surface quality of your final model.

A smaller layer height results in smoother finishes and finer details, but takes longer to print. A larger layer height reduces printing time but may slightly lower the visual quality. By fine-tuning the layer height settings in Orca Slicer, you can achieve the perfect balance between speed, precision, and visual appeal based on your project’s needs.

Importance of Layer Height Adjustment

Although layer height settings may seem less important compared to material, temperature, or flow rate adjustments, they play a crucial role in determining the final print quality. The layer height directly impacts how smooth, detailed, and structurally sound your 3D print will be.

Proper layer height adjustment in Orca Slicer can significantly enhance your printing results in the following ways:

- Produces a smoother surface finish with fewer or no structural deformities.

- Minimizes visible layer lines, giving the model a clean and polished appearance.

- Improves the sharpness of curved details, adding precision and definition to the print.

- Enhances the performance of overhangs, allowing for better accuracy and stability in complex designs.

Quick Reference Calculations

Nozzle Size | Min | Max | First Layer Height |

0.2mm | 0.04mm | 0.16mm | 0.12mm |

0.3mm | 0.06mm | 0.24mm | 0.18mm |

0.4mm | 0.08mm | 0.32mm | 0.25mm |

0.5mm | 0.10mm | 0.40mm | 0.30mm |

0.6mm | 0.12mm | 0.48mm | 0.35mm |

0.8mm | 0.16mm | 0.64mm | 0.45mm |

1.0mm | 0.20mm | 0.80mm | 0.55mm |

Layer Height Guidelines

Choosing the right layer height is essential for achieving high-quality prints, and it largely depends on your nozzle diameter. In Orca Slicer, the ideal layer height typically ranges between 20% and 80% of the nozzle diameter to ensure smooth extrusion and strong layer bonding.

Recommended Range

- Below 20% of the nozzle diameter: The print may develop surface inconsistencies, often appearing as small defects or a “fish scale” pattern, especially when printing at high speeds.

- Above 80% of the nozzle diameter: A layer height greater than this range can lead to poor layer adhesion, rough surfaces, and overall reduced print quality.

Maintaining the layer height within this 20–80% range ensures a perfect balance between print speed, surface smoothness, and structural integrity, helping you get the best possible results.

First Layer Height

The first layer height determines the thickness of the initial printed layer, which plays a major role in achieving strong bed adhesion and creating a stable base for the rest of the print. Setting this layer correctly helps reduce surface imperfections and ensures that the print sticks firmly to the build plate.

A thicker first layer improves adhesion and compensates for any minor unevenness on the bed surface, resulting in smoother prints with better overall quality.

Recommended First Layer Height Settings

- Recommended: 0.25 mm for a 0.4 mm nozzle (around 62.5% of the nozzle diameter).

- Maximum: Up to 65% of the nozzle diameter.

Layer Height Overhang Impacts

Layer height directly affects how well your printer handles overhangs and their angles. To achieve cleaner, more stable overhangs, it’s important to adjust the layer height to an optimal thickness based on the desired angle. In general, the lower the layer height, the better control you have over the overhang quality and stability.

Smaller Layer Height

When you use a smaller layer height, the printer can produce steeper overhangs with improved adhesion and smoother surface finishes. The shorter gap between unsupported layers helps maintain structural integrity and reduces the chances of sagging.

Larger Layer Height

A larger layer height increases the distance between unsupported layers, which can lead to poor adhesion and uneven surfaces. This often causes the layers to sag or deform, making it necessary to use supports for shallow overhang angles.

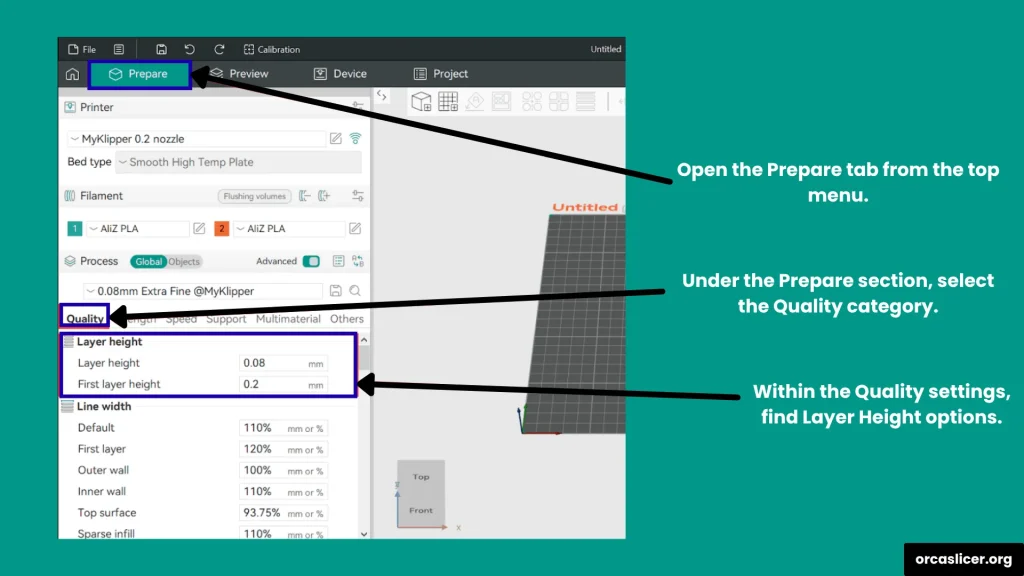

Settings in Orca Slicer for Layer Height

In Orca Slicer, you can easily configure layer height settings to control the precision, speed, and surface finish of your prints. These settings are found in the Prepare tab under the Quality submenu, where you can adjust the parameters for both the first layer and the remaining layers of your print.

How to Adjust Layer Height in Orca Slicer

- Open the Prepare tab in Orca Slicer.

- Go to the Quality tab from the submenu.

- Locate the Layer Height section.

- Set your layer height in millimeters according to your project’s requirements.

- Adjust the first layer height between 20% and 80% of the nozzle diameter, depending on your desired adhesion and print precision.

- Review and fine-tune other related parameters, such as print speed and temperature, based on your model’s dimensions.

- Once finalized, start your print to achieve balanced results in both quality and performance.

By using these settings in Orca Slicer, you can customize your layer configuration to produce smooth surfaces, strong adhesion, and accurate details suited to your 3D printing goals.