Air Filtration and Exhaust Fan Control

Every 3D printer is made up of key hardware parts that work together to ensure smooth and successful printing. One of the most important functions is air filtration, which keeps the chamber temperature stable while removing harmful fumes and particles from the air.

To achieve the best results, you need to control and coordinate all these hardware components properly. Managing each part with separate software can be time-consuming and difficult, which often slows down your printing process.

That’s why it’s better to configure your printer’s hardware directly within Orca Slicer. It allows you to handle air filtration, exhaust fans, and other connected parts in one place, saving time and keeping your prints consistent and safe.

How to Set Air Filtration and Exhaust Fan Control in Orca Slicer

Every slicer software uses different commands to manage printer components. In Orca Slicer, the command used to control the air filtration or exhaust fan is M106 P3. This command allows you to adjust fan behavior directly from within the slicer, making setup simple and efficient.

Check the Printer Firmware or Use Klipper

If your 3D printer is running Klipper firmware, you can automate several commands to make your printing process faster and more efficient. Klipper allows you to create Macros, which are sets of saved commands that can be reused anytime you need them.

For example, you can set M106 as a Macro to control different types of fans such as part cooling fans, auxiliary fans, and exhaust fans. This method helps you customize your airflow and temperature control to match your printing needs perfectly.

Below are the key settings and pin configurations you can use in Klipper to manage fan operations during the air filtration process. These keys and G-codes let you define how each fan works for optimal results.

Understanding Keys and G-code Commands

In Orca Slicer with Klipper, each fan or filtration component is assigned a unique key or G-code command. These commands tell the printer when and how each fan should operate. Understanding these control keys helps you manage:

- Airflow balance inside the printing chamber.

- Cooling timing for layers and materials.

- Filter activation for removing fumes and particles.

By mastering these G-code commands, you can take full control of your printer’s air filtration and exhaust system directly through Orca Slicer, improving print quality and maintaining a safe printing environment.

Concept of the Keys and G-code in Orca Slicer

Understanding the G-code commands and their parameters is important for proper fan control in Orca Slicer. These commands tell your printer how and when to activate different fans during the printing process.

M106 Command: The M106 command is used to activate the fans in Orca Slicer. It is the main command that controls airflow within the printing chamber.

P Parameter: The P parameter defines which specific fan the command will control. Each fan in the printer is assigned a separate parameter value.

P2 Parameter: Controls the Auxiliary Fan

P3 Parameter: Controls the Exhaust Fan

S Parameter: The S parameter controls the fan speed, with values ranging from 0 to 255. In Orca Slicer, these values are shown as a percentage scale (0–100%) and are usually calibrated as 0–10 when sending G-code to your 3D printer.# rather than applying [fan], we assign the standard cooling fan using [fan_generic] in this section

# this fan controls the primary cooling during printing

[fan_generic fan0]

pin: PA7

cycle_time: 0.01

hardware_pwm: false

# this one operates as an extra fan for additional airflow

# remove these lines if your setup doesn’t include an extra fan

[fan_generic fan2]

pin: PA8

cycle_time: 0.01

hardware_pwm: false

# this fan handles the air removal or ventilation process

# delete these entries if your printer setup lacks an exhaust unit

[fan_generic fan3]

pin: PA9

cycle_time: 0.01

hardware_pwm: false

[gcode_macro M106]

gcode:

{% set fan = 'fan' + (params.P|int if params.P is defined else 0)|string %}

{% set speed = (params.S|float / 255 if params.S is defined else 1.0) %}

SET_FAN_SPEED FAN={fan} SPEED={speed}By combining these commands and parameters, you can manage your printer’s air filtration and exhaust system effectively, keeping your prints clean, precise, and free from harmful fumes.

Air Filtration and Exhaust Fan Control Settings in Orca Slicer

Setting up air filtration and exhaust fan control in Orca Slicer is simple once you know where to find the right options. Follow these steps to configure the fans according to your printer and material needs.

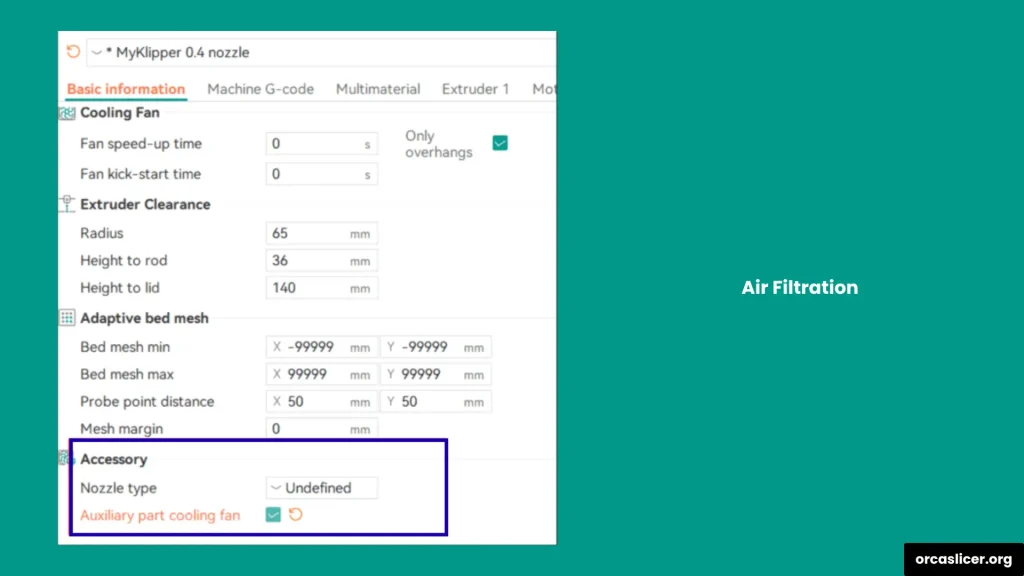

Printer Settings

- Open Orca Slicer.

- Go to Printer Settings.

- Select Auxiliary Part Cooling Fan.

- Depending on your Orca Slicer version, these options can be found under:

- General Options, or

- Advanced Options.

- Use this section to assign and control your auxiliary and exhaust fans for stable temperature and smooth airflow.

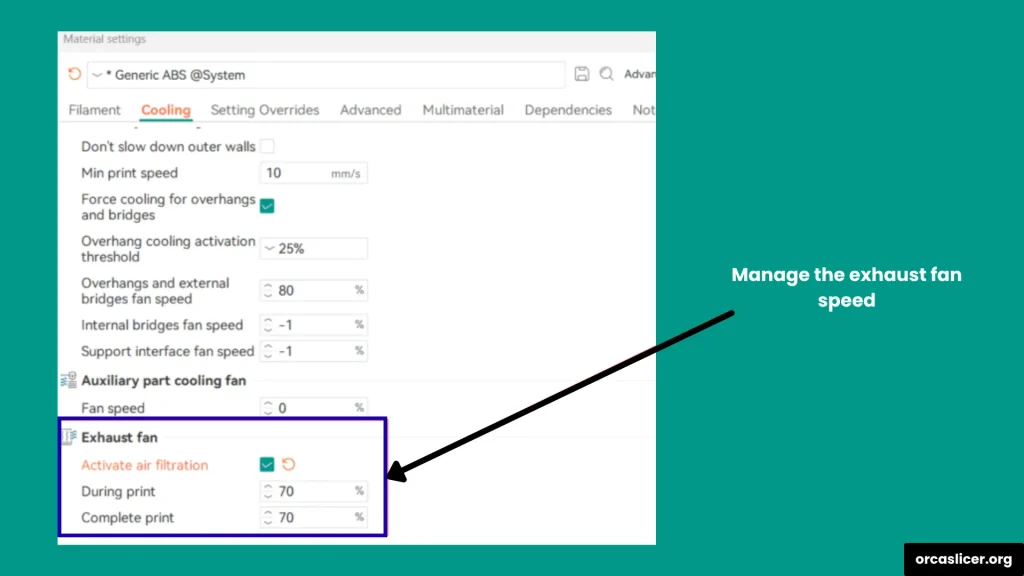

Material Settings

- Navigate to the Material Settings tab.

- Open Fan Settings.

- Choose both Auxiliary Part Cooling Fan and Exhaust Fan.

- A fan speed box (0–100%) will appear.

- Select your preferred speed percentage.

- Orca Slicer automatically sends this as a G-code command (M106 with S value) to your printer.

Tip: Setting the right fan speed helps control chamber temperature, remove fumes effectively, and improve overall print quality.

By configuring these options correctly, you can ensure your printer maintains optimal chamber conditions, improves print quality, and efficiently removes fumes through proper air filtration and exhaust fan control.