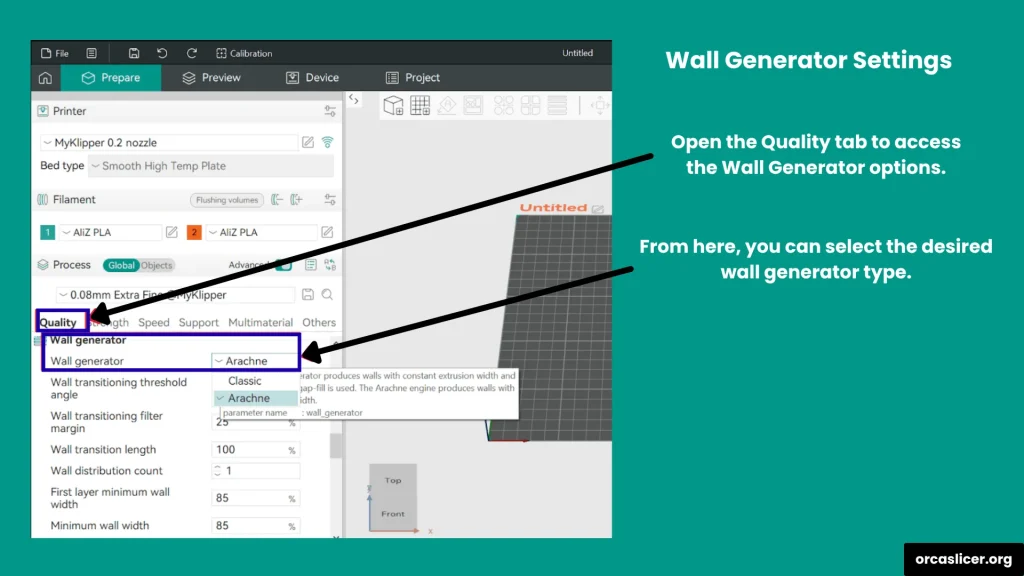

Wall Generator Settings

The Wall Generator Settings in Orca Slicer define how your printer creates the inner and outer walls (perimeters) of a 3D print. By optimizing these settings, you can enhance print strength, surface smoothness, and dimensional accuracy, all while minimizing defects like gaps or uneven surfaces. You can access the Wall Generator options under the Quality Settings tab in Orca Slicer.

Classic Wall Generator

The Classic wall generator prints each wall at a fixed line width and flow rate. The extrusion remains constant throughout the process, without adapting to the model’s varying geometry.

This method offers stable extrusion and fast print times, making it ideal for standard prints that don’t require precision in thin or variable-width areas. However, it may skip very narrow regions that fall below the defined wall width since it doesn’t adjust dynamically.

Best for:

- Simple and regular-shaped models.

- Fast printing where precision is less critical.

Arachne Wall Generator

The Arachne wall generator uses an adaptive extrusion algorithm that automatically adjusts the line width depending on the geometry of the model. This means the printer can thin or widen the extrusion path dynamically to print small features, fine details, and smooth transitions without leaving gaps.

Advantages:

- Smooth transitions between thick and thin walls.

- Improved dimensional accuracy in fine features.

- Better surface quality and fewer visible seams.

Best for:

- Models with thin walls or detailed geometry.

- Prints requiring smooth transitions between perimeters.

Wall Transitioning Threshold Angle

This setting defines the minimum angle that triggers the transition between even and odd wall counts.

- A lower angle improves print accuracy but can cause over-extrusion in tight corners.

- A higher angle speeds up transitions but may skip center walls in wedge-shaped areas.

Recommended Range: 30°–50°, depending on model complexity.

Wall Transitioning Filter Margin

When the slicer quickly switches between 1, 2, or 3 walls during printing, it can cause visible seams or artifacts on the surface. The Wall Transitioning Filter Margin helps prevent this by smoothing out those transitions and maintaining a steady extrusion flow.

It adds a tolerance range to avoid unnecessary switching between wall counts.

Example Formula: [MinimumWallWidth − Margin, 2 × MinimumWallWidth + Margin]

Tip:

- A higher margin minimizes switching but may slightly reduce detail accuracy.

- A balanced margin (around 10–20% of nozzle diameter) gives smooth, consistent wall quality.

Wall Transitioning Length

This controls how gradually the printer adjusts between thick and thin walls.

- Shorter values: Faster transitions but may remove inner walls or reduce print quality.

- Longer values: Smoother transitions but slightly longer print time.

Recommendation: Keep this moderate to balance quality and print speed.

Wall Distribution Count

When extrusion width changes during printing, the Wall Distribution Count limits how many walls can vary in width.

- Lower values: Fewer walls vary, giving smoother outer surfaces and consistent wall quality.

- Higher values: More inner walls adjust width dynamically for a tighter fit.

Tip: Set it between 2–4 walls for best balance between strength and surface precision.

Minimum Wall Width

This is the thinnest wall width the printer will generate, expressed as a percentage of nozzle diameter. If the slicer detects a thinner wall than this setting, it prints at the defined minimum instead of skipping it entirely.

Example: If your nozzle diameter is 0.4mm and the minimum wall width is 50%, the slicer will not print walls thinner than 0.2mm.

First Layer Minimum Wall Width

The first layer determines adhesion and stability. This setting defines the minimum width of the first-layer walls, ensuring a strong foundation.

Recommendation: Keep the value equal to or slightly above the nozzle diameter for better bed adhesion and a solid base layer.

Minimum Feature Size

This defines the smallest printable feature size, also expressed as a percentage of nozzle diameter. If a feature is thinner than this value, the slicer either skips it or adjusts its thickness to match the minimum printable width.

Tip: Keep this between 60–80% of nozzle diameter to maintain small details while avoiding weak walls.

Minimum Wall Length

This controls the shortest segment length the printer will print. Any wall shorter than this threshold is automatically skipped. This prevents unnecessary micro-walls that waste filament and cause inconsistent surfaces, improving both speed and stability.

Tip: Keep it small enough to preserve fine details but large enough to avoid printing unconnected lines.

Important Note:

These wall generator settings do not affect top and bottom layers, ensuring smooth, consistent surface finishes without impacting perimeters.

- In Advanced Settings, the One Wall Threshold value adjusts single-wall top surfaces.

- If this setting is above 0.5, or if single-wall top surfaces are enabled, these wall generator settings apply to the top layer as well.

Pro Tips for Better Wall Quality

- Use Arachne for adaptive, precise printing and Classic for fast, standard prints.

- Calibrate your extrusion multiplier before adjusting wall generator settings.

- Keep transitioning values moderate to avoid artifacts or visible seams.

- Increase minimum wall width and feature size slightly for higher reliability on small parts.

- For fine details, pair Arachne mode with Precise Wall settings for perfect dimensional accuracy.