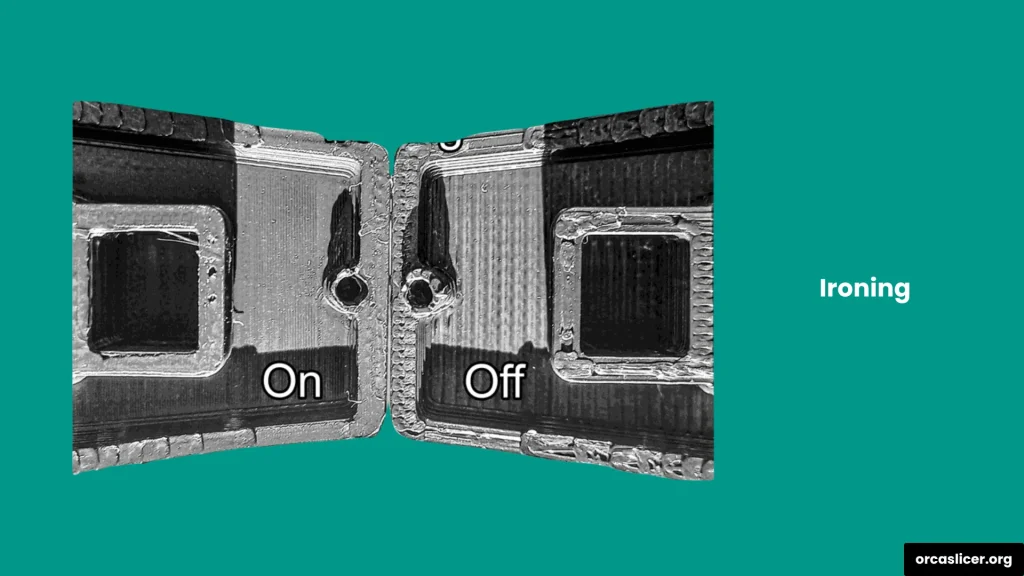

Ironing

In 3D printing, techniques used to smooth and even out the top layer of a print are known as Ironing. The top surface of a printed model can often show visible lines, gaps, or small imperfections, which reduce the professional quality of the final piece. Orca Slicer provides advanced ironing settings that help you fix these surface defects efficiently by reprinting the top layer with a controlled flow rate and motion pattern.

Ironing ensures your top layers have a clean, glossy finish, improving both appearance and texture without needing post-processing. Let’s explore how these settings work and how you can configure them for the best possible results.

Ironing Settings

During ironing, a second layer is printed directly over the final top layer at the same height, but with a lower flow rate and a defined pattern. This gentle, smooth extrusion evens out inconsistencies and fills micro-gaps, producing a polished and uniform top surface.

While ironing greatly enhances print quality, it also increases print time and requires careful temperature management. Because the nozzle stays hot longer during slow movement, you must ensure proper hot-end cooling to avoid heat creep or nozzle clogging.

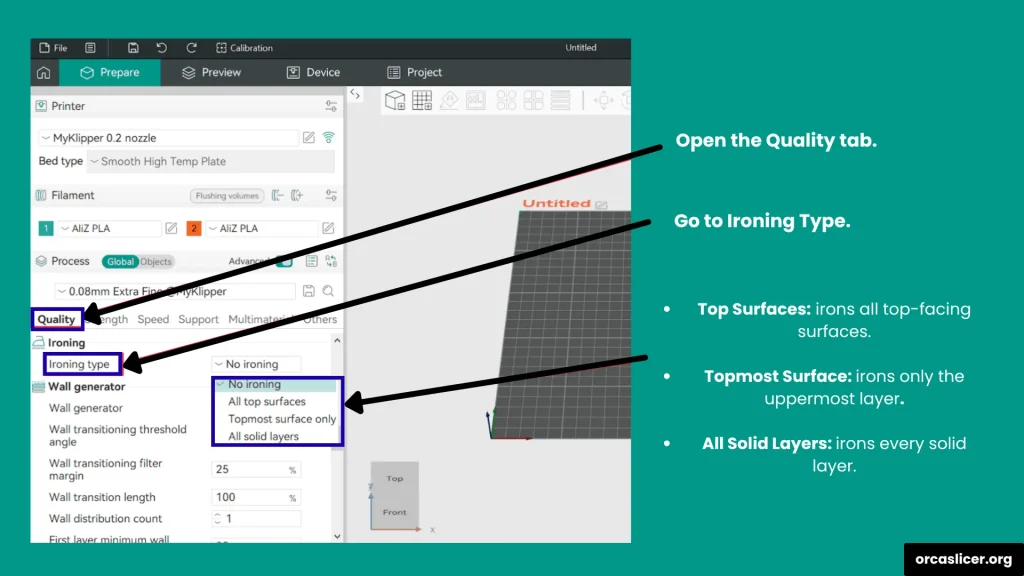

Type

You can select which surfaces or layers you want to apply ironing to:

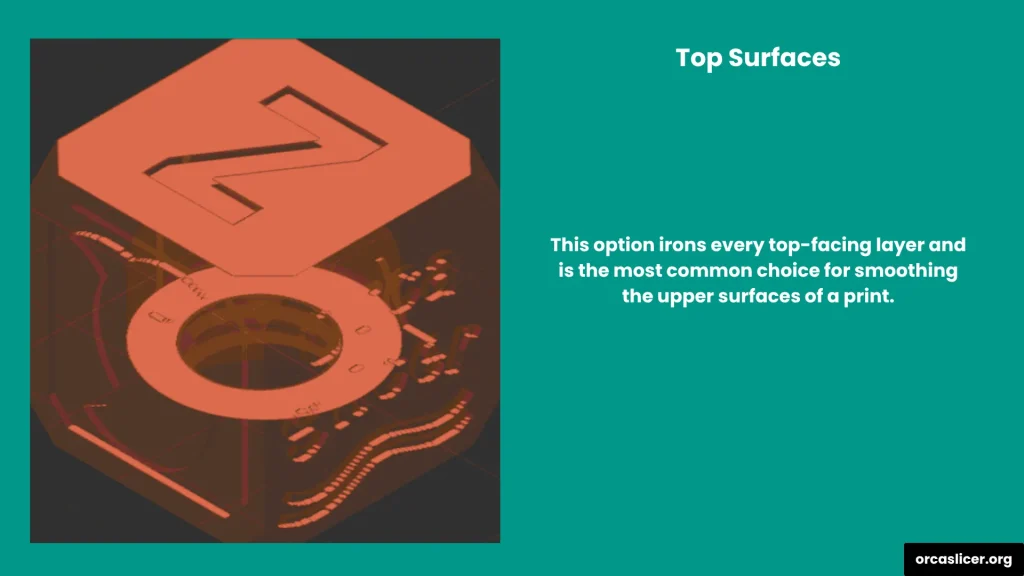

- Top Surfaces: Applies ironing to all top-facing surfaces. This is the most commonly used option for achieving a smooth appearance across all top layers.

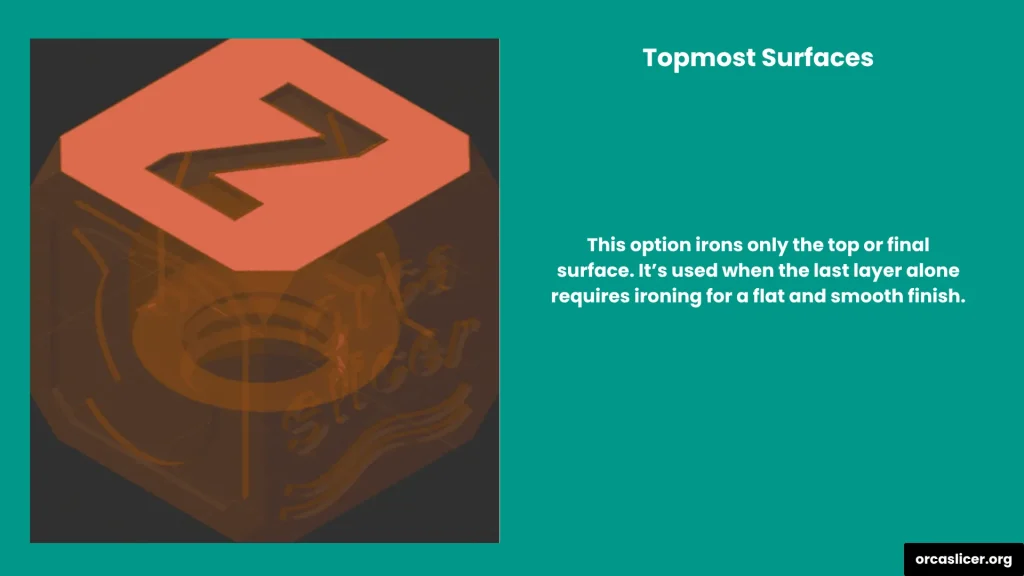

- Topmost Surface: Irons only the final top layer, ideal for finishing prints that only need the visible surface polished.

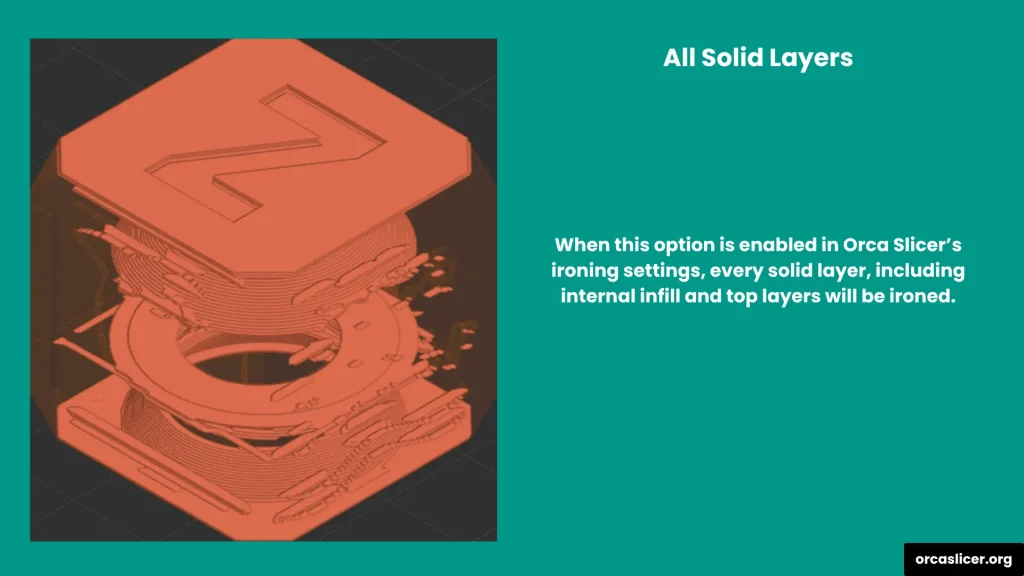

- All Solid Layers: Irons every solid layer, including internal infill and top layers. This option produces a dense, smooth structure but increases print duration significantly.

Tip: Choose this setting only when you need exceptionally high-quality surfaces or functional parts with dense upper layers.

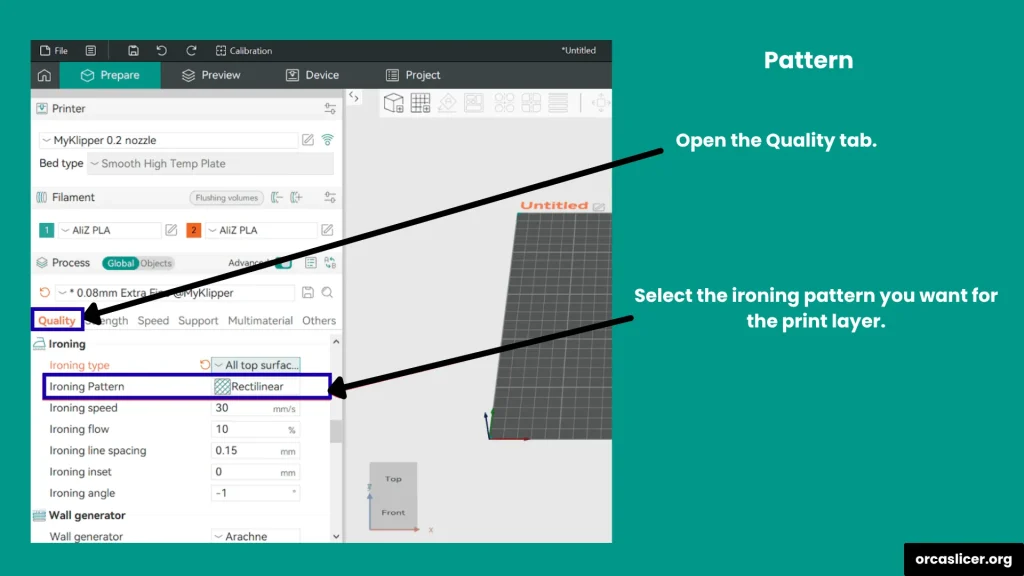

Pattern

The pattern defines how the nozzle moves during ironing, affecting the surface smoothness and appearance. Common patterns include:

- Concentric: Best for circular or rounded models, offering excellent visual appeal.

- Rectilinear: Ideal for flat or angular models, providing balanced coverage and consistency.

Selecting the right pattern helps ensure complete surface coverage and even texture.

Flow

The flow value determines how much filament is extruded during ironing. It’s usually set as a percentage of the normal extrusion flow.

- Lower Flow: Produces a smoother finish but may leave small gaps if too low.

- Higher Flow: Provides stronger coverage but can cause over-extrusion and a bulky top surface.

Recommended Range: 5%–20% of normal flow rate for optimal surface quality.

Line Spacing

Line spacing controls the distance between ironing lines, usually expressed as a percentage of filament diameter.Smaller line spacing improves smoothness and consistency, while larger spacing speeds up printing but may leave faint lines.

Recommended Range: 10%–25% of filament diameter for best surface finish.

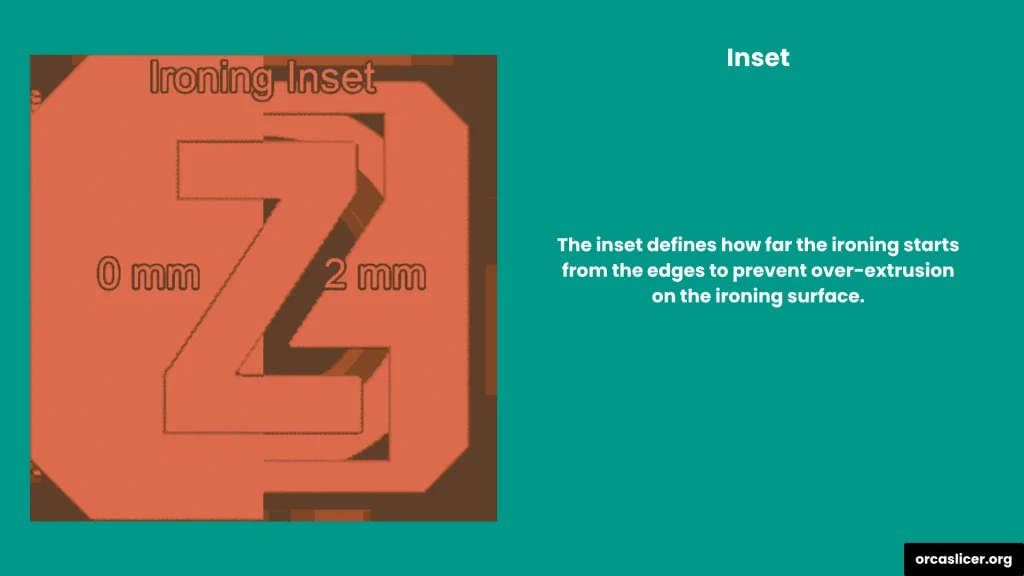

Inset

Inset defines how far the ironing starts from the edges of the model to prevent over-extrusion near the perimeter.

- Inset = 0: Ironing begins directly at the edge, smoothing the entire top surface but risking small filament buildups on corners.

- Inset > 0: Keeps a safe margin from the edges, reducing boundary artifacts.

Adjust and test the inset value to find the best balance between smooth edges and perfect corners.

Angle

This defines the direction or angle of the ironing movement:

- Positive Values: Set a defined ironing angle to match or contrast the infill direction.

- Negative Values: Disable angle control and let the printer follow the infill direction, printing the top layer along existing paths for smoother blending.

Using alternating angles between layers can enhance texture uniformity and reduce visible lines.

Speed

The ironing speed controls how fast the nozzle moves during the final smoothing pass.Printing at a lower speed allows more consistent flow and better surface blending, while higher speeds reduce print time but may cause visible streaks.

Recommended Range: 15–30 mm/s for best results.

Key Tips for Perfect Ironing

- Always ensure effective hot-end cooling to prevent heat buildup.

- Use lower flow and smaller line spacing for fine models requiring premium finishes.

- Apply ironing only to topmost layers unless structural density is required.

- Combine concentric patterns with low speed for the smoothest and most uniform top surfaces.