Line Width

In line width settings, you can control the width of each filament line extruded from the nozzle. The correct adjustment of this setting ensures strong layer adhesion, smooth surfaces, and accurate dimensions in your 3D prints.

A poorly optimized line width can cause several issues, including weak layer bonding, visible gaps, surface swelling, and loss of fine details. If the line width is too thin, the print may appear fragile and have gaps between lines. On the other hand, if it is too thick, the print can look bulky, lose precision, and show surface irregularities.

Line Width Settings

The line width settings determine the exact width of the filament extruded from the nozzle. These settings play a vital role in controlling print quality, surface finish, and structural strength. You can configure the line width in two ways:

- Fixed Value (mm): Manually set a specific width in millimeters.

- Percentage of Nozzle Diameter: Define the width as a percentage of your nozzle size.

Important Note: When you configure the line width as a percentage, Orca Slicer automatically adjusts the width whenever the nozzle diameter changes. This helps maintain consistent print quality without requiring manual recalibration.

Recommended Line Width Settings

- Line Width = 100% of Nozzle Diameter: This is the ideal starting point. Setting your line width equal to your nozzle diameter usually gives balanced print quality and dimensional accuracy.

- Line Width < 100% of Nozzle Diameter: A lower value can cause gaps, weak layer adhesion, or incomplete infill, leading to fragile prints.

- Line Width > 100% of Nozzle Diameter: Setting the width between 100% and 150% of the nozzle diameter helps achieve better layer bonding, stronger prints, and improved infill density. However, going above 150% may cause surface blobs, rough textures, and dimensional inaccuracies.

Advantages of Thicker Filament Lines

- Improves layer bonding and overall print strength.

- Enhances internal structures such as infill and inner walls.

- Helps achieve better packing density for solid parts.

At 100% line width, the filament may appear slightly thinner when first extruded, but gradually flattens to match the nozzle diameter as printing progresses, ensuring smooth and consistent layers.

Line Types and Their Settings

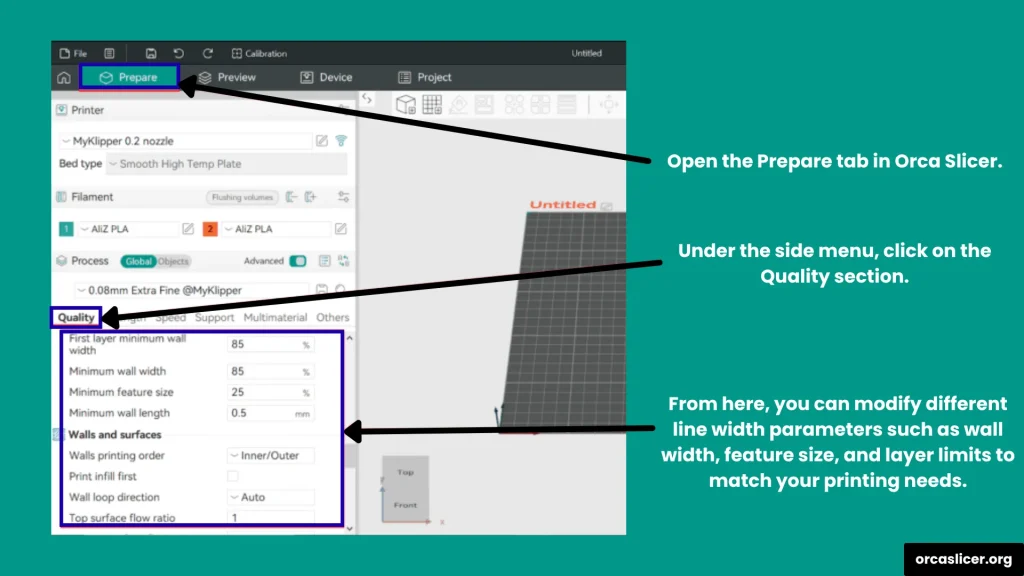

In Orca Slicer, you can fine-tune different line types to control print strength, dimensional accuracy, and visual appearance. These settings are available under the Prepare tab in the Quality sub-menu. Each line type serves a specific purpose, and optimizing them ensures smooth, stable, and precise printing results.

Default

This is the fallback value used when no specific width is set for a line type. The default is 0, meaning the slicer will use general print settings unless customized further.

First Layer

The first layer is crucial for bed adhesion and print stability. Using a slightly thicker line width helps even out surface imperfections and improves the bond between the print and the bed.

Recommended: Slightly wider than the nozzle diameter for better adhesion and stability.

Outer Wall

The outer wall forms the visible exterior surface of your print. It directly affects surface quality and dimensional accuracy. Keeping this line type slightly thicker ensures sharp, detailed overhangs and precise shapes.

Recommended: 105%–120% of the nozzle diameter for the best balance of strength and quality.

Inner Wall

The inner wall provides internal support and strengthens the model’s structure. Setting it slightly wider than the outer wall enhances layer bonding and overall durability.

Recommended: ≥120% of the nozzle diameter for improved structural integrity.

Top Surface

The top surface determines the visual quality of the uppermost layer of your print. It should be smooth and free from overextrusion marks.

Recommended: 100%–105% of the nozzle diameter to achieve a clean, even finish.

Sparse Infill

Sparse infill defines the internal lattice or grid that supports the outer shell without using excessive material.

Recommended: Around 115% of the nozzle diameter to maintain good layer adhesion while reducing print time. For additional strength, adjust the infill line multiplier.

Internal Solid Infills

Used for top and bottom solid layers or regions requiring 100% infill. A slightly thicker line width ensures a smoother surface and better bonding between layers.

Recommended: Around 110% of the nozzle diameter for strong adhesion and a polished appearance.

Support

Support structures hold up overhangs and complex geometries during printing. They need to be sturdy enough to support the print but easy to remove afterward.

Recommended: 100% of the nozzle diameter to achieve a balanced structure that is neither too fragile nor too dense.