Adaptive Bed Mesh

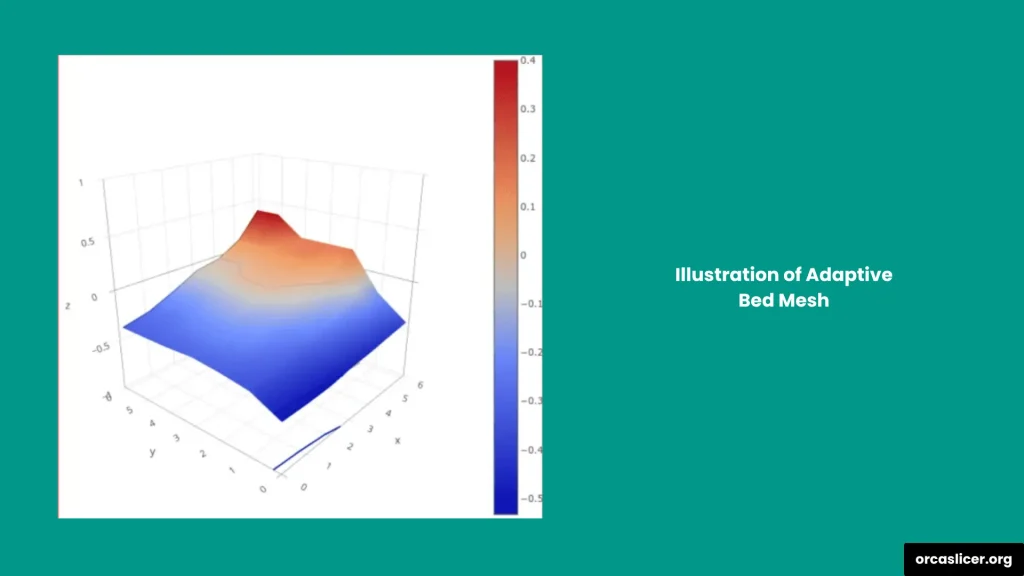

In simple terms, an Adaptive Bed Mesh (ABM) is a feature that focuses on probing and leveling only the specific area of the print bed where your model will be printed, instead of scanning the entire surface.

For example, if you’re printing a cup, the adaptive mesh will analyze and level just the base area of the cup, not the whole bed. This smart targeting makes the process faster, more efficient, and more accurate, leading to better first-layer adhesion and improved overall print quality.

If your slicer doesn’t support ABM, you may face issues like slower printing or minor flaws in dimensional accuracy. Fortunately, Orca Slicer has built-in Adaptive Bed Mesh support, so you don’t need any additional tools or plugins.

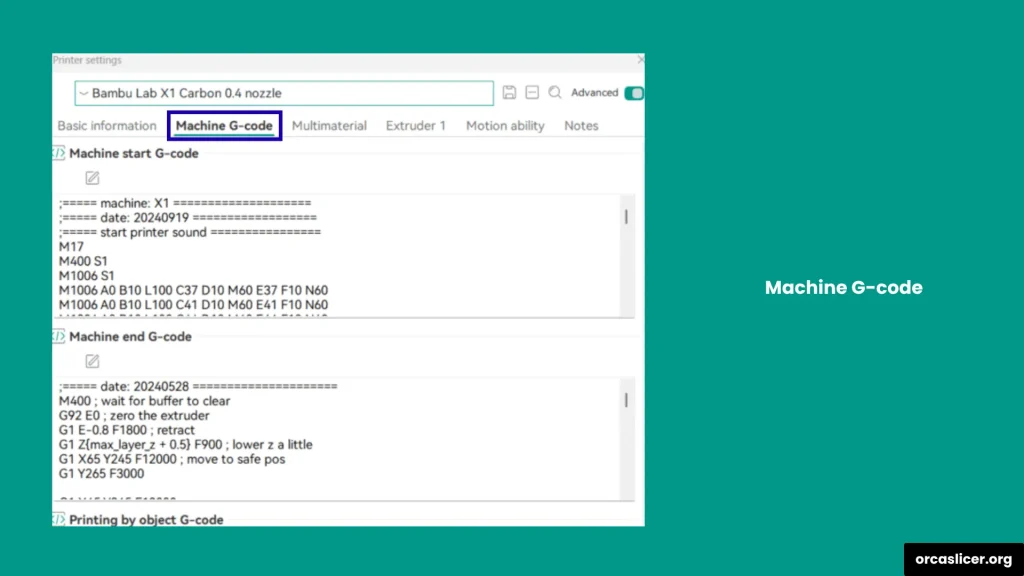

You can easily integrate ABM into your Machine Start G-code within Orca Slicer. With just a few adjustments, the slicer automatically generates the adaptive mesh area before every print, ensuring precise leveling, reduced print time, and a perfect first layer every time.

ABM Settings in Orca Slicer for Different Firmwares

In Orca Slicer, you can easily set up and control Adaptive Bed Mesh (ABM) for different 3D printer firmwares such as Klipper, RepRapFirmware (RRF), and Marlin. These settings help you manage the bed probing process precisely, ensuring that your print starts on a perfectly leveled surface.

To access these options, go to Printer Settings and open the Basic Information tab. Here, you will find all available Bed Mesh Settings for your printer. Orca Slicer allows you to integrate and adjust these configurations without needing any external software.

Settings in Orca Slicer

Bed Mesh Min

Most 3D printers have a limited XY offset, which prevents them from probing the entire print bed. The Bed Mesh Min option lets you define the minimum bed area that the printer can probe safely. Orca Slicer automatically optimizes the adaptive_mesh_bed_min and adaptive_mesh_bed_max values to keep them within the correct range.

- The default value (-99999, -99999) means no minimum limit is set.

- You can manually enter your printer’s specific minimum values provided by the manufacturer to prevent the probe from moving outside the bed area.

Bed Mesh Max

Similar to the minimum value, the Bed Mesh Max option defines the maximum probing area of your bed. Since most printers don’t have preset limits, the default value (99999, 99999) means no restriction on the XY probing range.

Using Orca Slicer, you can specify the exact maximum boundary to ensure your probe works only within the printable area, improving safety and accuracy.

Probe Point Distance

This setting defines the distance between each probe point in the X and Y directions on the bed mesh. The default distance is usually 50 mm, but you can modify it to increase or decrease mesh density based on your printer’s accuracy and bed size.

Mesh Margin

The Mesh Margin option lets you add a small distance or buffer around the adaptive bed mesh area.

Note: In Orca Slicer, all settings already include margin values, so keeping your margin set to 0 gives you exact mesh boundaries. For Klipper users, set the Mesh Margin to 0 in your configuration file when using the BED_MESH_CALIBRATE command.

G-code Variables for Adaptive Bed Mesh Commands

Understanding the G-code variables used for ABM will help you fine-tune your printer’s bed leveling performance.

- bed_mesh_probe_count: Defines the number of probe points in the X and Y directions. It’s calculated based on the distance between probe points and the overall size of the mesh area.

- adaptive_bed_mesh_min: Represents the starting coordinate of the probing area and defines the minimum X and Y positions of the mesh.

- adaptive_bed_mesh_max: Defines the ending coordinate of the probing area, setting the maximum X and Y limits of the adaptive bed mesh.

To access these options, go to Printer Settings and open the Basic Information tab. Here, you will find all available Bed Mesh Settings for your printer. Orca Slicer allows you to integrate and adjust these configurations without needing any external software.

Algorithm for Adaptive Bed Mesh Interpolation

For Klipper firmware users, missing points or delays during probing are handled through adaptive bed mesh interpolation.

- If the probe count is less than 4, the algorithm used is Lagrange, which estimates missing points mathematically.

- When all probe points are normal, the system automatically switches to the Bicubic algorithm for smoother and more accurate surface mapping.

By configuring these ABM settings in Orca Slicer, you ensure your printer probes only the necessary area with precise accuracy, leading to better first-layer adhesion, smoother prints, and faster calibration across all supported firmware types.

Examples of ABM Settings in Orca Slicer for Klipper, Marlin and RRF

Marlin:

; Marlin don't support specify the probe count yet, so we only specify the probe area

G29 L{adaptive_bed_mesh_min[0]} R{adaptive_bed_mesh_max[0]} F{adaptive_bed_mesh_min[1]} B{adaptive_bed_mesh_max[1]} T V4Klipper:

; Always pass `ADAPTIVE_MARGIN=0` because Orca has already handled `adaptive_bed_mesh_margin` internally

; Make sure to set ADAPTIVE to 0 otherwise Klipper will use it's own adaptive bed mesh logic

BED_MESH_CALIBRATE mesh_min={adaptive_bed_mesh_min[0]},{adaptive_bed_mesh_min[1]} mesh_max={adaptive_bed_mesh_max[0]},{adaptive_bed_mesh_max[1]} ALGORITHM=[bed_mesh_algo] PROBE_COUNT={bed_mesh_probe_count[0]},{bed_mesh_probe_count[1]} ADAPTIVE=0 ADAPTIVE_MARGIN=0RRF:

M557 X{adaptive_bed_mesh_min[0]}:{adaptive_bed_mesh_max[0]} Y{adaptive_bed_mesh_min[1]}:{adaptive_bed_mesh_max[1]} P{bed_mesh_probe_count[0]}:{bed_mesh_probe_count[1]}